What is Machine Vision?

Machine vision is a technology that enables automated image-based inspection and analysis for industrial and manufacturing processes. It combines advanced cameras, sensors, and artificial intelligence (AI) to capture, process, and interpret visual information. By leveraging machine vision, industries can automate complex tasks, ensure higher precision, and reduce human intervention.

Unlike computer vision, which has broader applications like facial recognition and autonomous vehicles, machine vision focuses specifically on industrial applications. It plays a critical role in improving efficiency and maintaining quality standards across various sectors.

How Machine Vision Is Transforming Key Industries

Machine vision technology is a game-changer for industries seeking to optimize their operations. Its applications span defect detection, assembly verification, dimension measurement, and robotic guidance. By integrating AI algorithms and machine learning, machine vision systems provide unparalleled accuracy, enabling industries to meet stringent quality and safety requirements.

For instance, in Industry 4.0, smart factories rely heavily on machine vision to drive automation. Learn more about Industry 4.0 and its impact on modern industries.

Benefits of Machine Vision Systems

The benefits of machine vision systems include:

- Enhanced Precision: Reduces errors in inspection processes.

- Increased Productivity: Speeds up production lines by automating inspection tasks.

- Cost Efficiency: Minimizes waste by detecting defects early.

- Improved Safety: Automates hazardous tasks, reducing risks for human workers.

Statistics reveal that implementing machine vision can increase production efficiency by up to 30% (Source: Deloitte). These advantages make it an indispensable tool for industries focused on quality and productivity.

Five Industries Leading with Machine Vision

Machine vision has been widely adopted in several industries. Below, we delve into five sectors where this technology is making a significant impact.

Manufacturing Industry (+ Examples)

Machine vision in manufacturing is revolutionizing quality control by identifying defects, ensuring uniformity, and verifying product dimensions. For example:

- Defect Detection: High-speed cameras detect surface flaws in real-time.

- Assembly Verification: Ensures that components are assembled correctly.

Companies like Humphrey Automation use machine vision for industrial manufacturing automation solutions, reducing inspection times and improving accuracy.

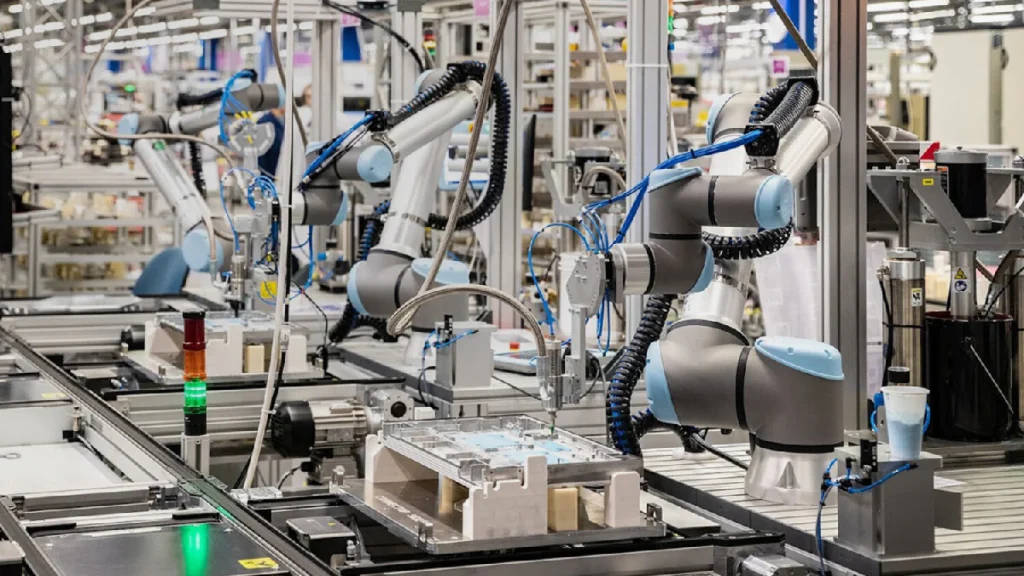

Robotics Industry (+ Examples)

Machine vision in robotics enhances the capabilities of automated systems. Robots equipped with vision systems can identify objects, navigate environments, and perform complex assembly tasks.

- Example 1: Robotic arms in electronics manufacturing use machine vision to align components with micron-level precision, ensuring accuracy during assembly.

- Example 2: Warehouse robots employ machine vision for object recognition and pathfinding, improving logistics efficiency.

Machine vision’s ability to adapt to different tasks makes it indispensable for robotics, particularly in high-mix, low-volume production environments. Learn how custom engineering solutions integrate machine vision into robotic systems for various applications.

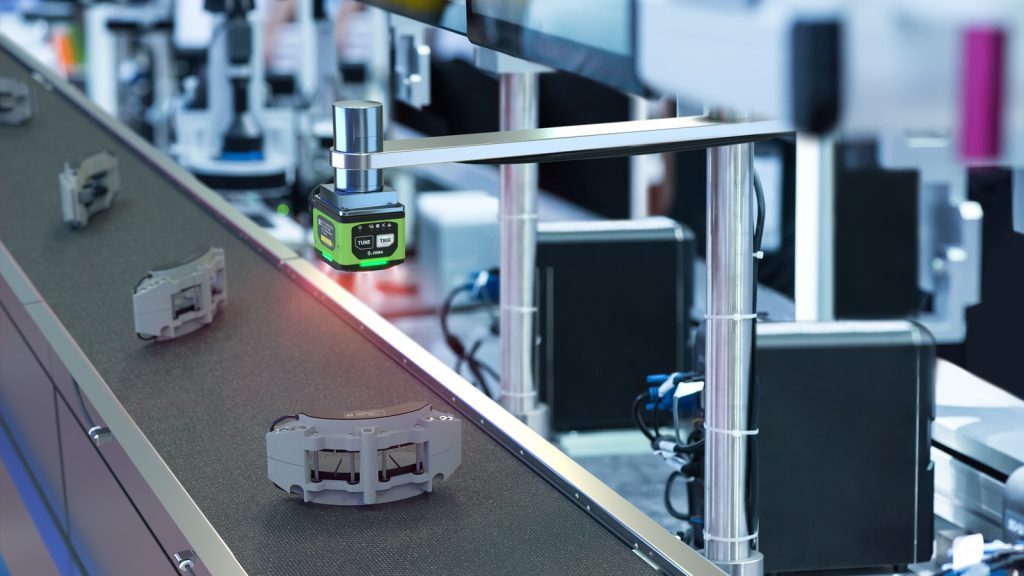

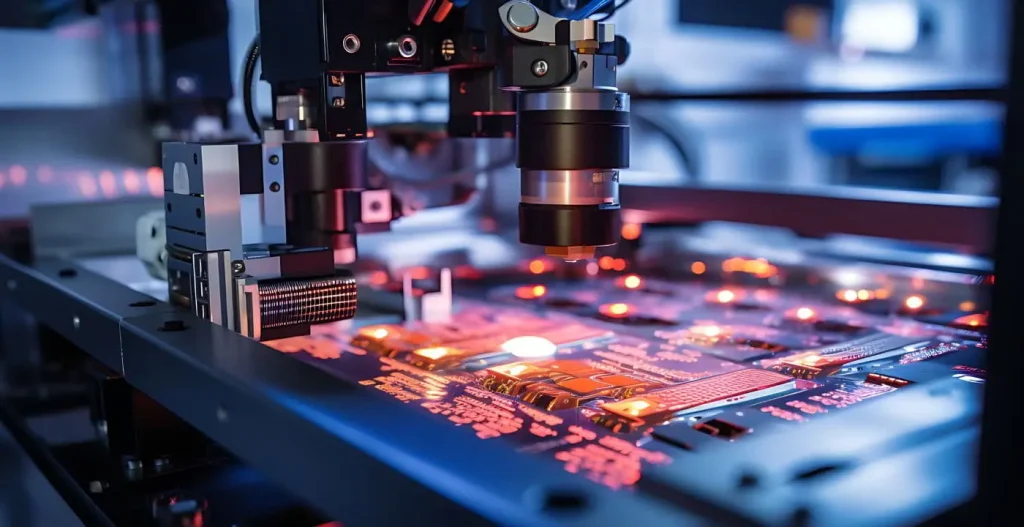

Electronics Industry (+ Examples)

The electronics industry relies on machine vision to inspect microchips, circuit boards, and other components for defects that are imperceptible to the human eye.

- Example 1: Semiconductor process automation leverages machine vision to detect wafer defects and ensure uniformity.

- Example 2: Machine vision systems analyze solder joints on circuit boards, ensuring connectivity and reliability.

This technology has become vital in ensuring quality in miniaturized and complex electronic components, where manual inspection is impractical. Explore more about semiconductor process automation and its reliance on machine vision technologies.

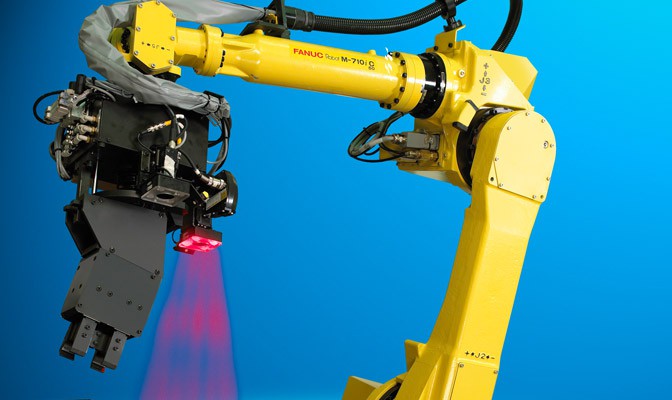

Automotive Industry (+ Examples)

Machine vision in the automotive industry is critical for ensuring the safety and reliability of vehicles. Applications include:

- Inspection: High-resolution cameras detect paint defects, dents, and misalignments during vehicle production.

- Guidance for Autonomous Vehicles: Machine vision enables lane detection, traffic sign recognition, and obstacle avoidance.

- Example: Automotive companies use machine vision for inspecting weld seams and ensuring compliance with safety standards.

Suppliers like Siemens and Inspekto offer solutions like the Inspekto S70 to enhance inspection processes in automotive manufacturing.

Agriculture Industry (+ Examples)

Machine vision in agriculture, also known as agritech automation, helps farmers optimize crop yields and reduce waste. Examples include:

- Crop Monitoring: Machine vision systems analyze plant health using spectral imaging, detecting pests and nutrient deficiencies.

- Precision Farming: Drones equipped with machine vision guide the application of fertilizers and pesticides, minimizing waste.

- Automated Harvesting: Vision-guided robots selectively harvest fruits and vegetables, reducing damage and increasing efficiency.

Machine vision’s role in agriculture extends to grading and sorting produce, ensuring uniform quality standards for consumers. Learn more about agritech automation and its transformative impact on farming practices.

Future with Machine Vision

The future of machine vision technology promises further advancements, such as:

- AI Integration: Smarter algorithms for more accurate inspections.

- 3D Vision Systems: Enhanced capabilities for depth perception and complex object analysis.

- Cloud Connectivity: Real-time data sharing and analytics.

These innovations will continue to expand the applications of machine vision across industries, driving efficiency and innovation.

Conclusion

Machine vision technologies are reshaping industries by providing precise, efficient, and cost-effective solutions. From manufacturing to agriculture, their applications are vast and varied. By adopting machine vision, businesses can stay competitive and meet the growing demands of modern markets.As we look to the future, technologies like the Inspekto S70 and advancements in AI will pave the way for even greater possibilities. Investing in machine vision today ensures a smarter, more efficient tomorrow.