Pneumatic systems offer robust solutions for enhancing automation in various industrial settings. Their reliability, speed, and versatility make them ideal for optimizing processes, improving efficiency, and boosting productivity. At Pneumation.ca, we specialize in providing top-quality pneumatic components and expertise to help you get the most out of your automation systems. In this article, we explore five effective ways to enhance your automation system using pneumatics, ensuring your operations are as efficient and effective as possible.

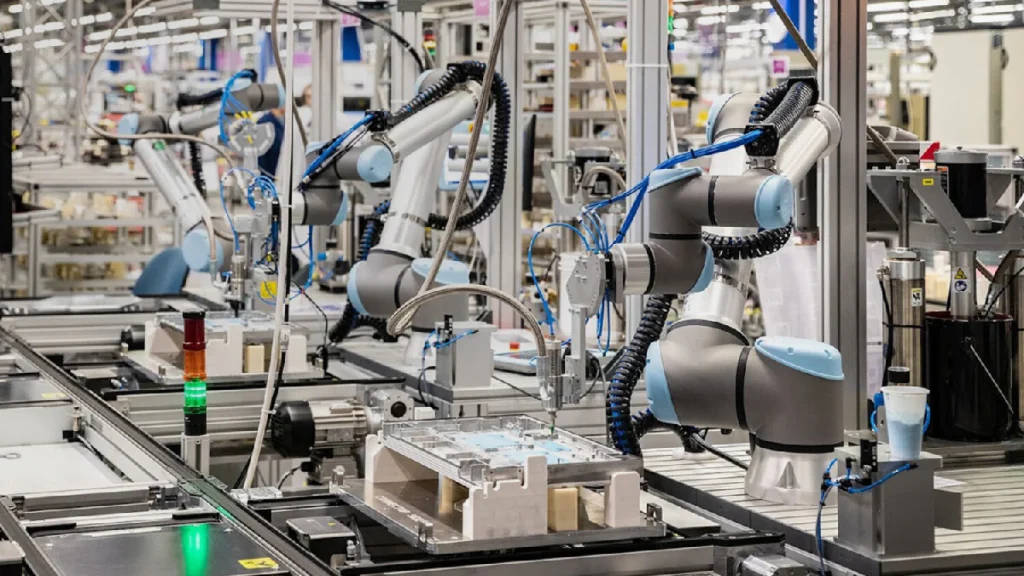

1. Upgrade to Advanced Pneumatic Actuators

- Enhanced Precision and Control: Advanced pneumatic actuators, such as those with integrated sensors and feedback systems, provide greater precision and control over automation processes. By incorporating these actuators, you can achieve more accurate positioning and motion control in applications like material handling, assembly, and packaging.

- Faster Cycle Times: Modern pneumatic actuators are designed to operate with faster cycle times, which can significantly improve the speed and efficiency of your automation system. This is especially beneficial in high-speed production environments where quick and reliable actuation is crucial.

Example: Upgrading to a high-performance rodless pneumatic actuator can enhance the efficiency of a pick-and-place operation by providing smooth, linear motion with minimal maintenance.

2. Implement Pneumatic Conveying Systems

- Efficient Material Handling: Pneumatic conveying systems use compressed air to transport bulk materials through pipelines, offering a clean and efficient method for moving powders, granules, and other materials. This can streamline your material handling processes, reduce manual labor, and minimize product contamination.

- Flexible Design: Pneumatic conveying systems can be easily customized to fit various layouts and operational requirements, making them a versatile solution for different types of automation applications.

Example: Integrating a pneumatic conveying system into your manufacturing line can automate the transfer of raw materials from storage bins to processing equipment, enhancing workflow efficiency and reducing downtime.

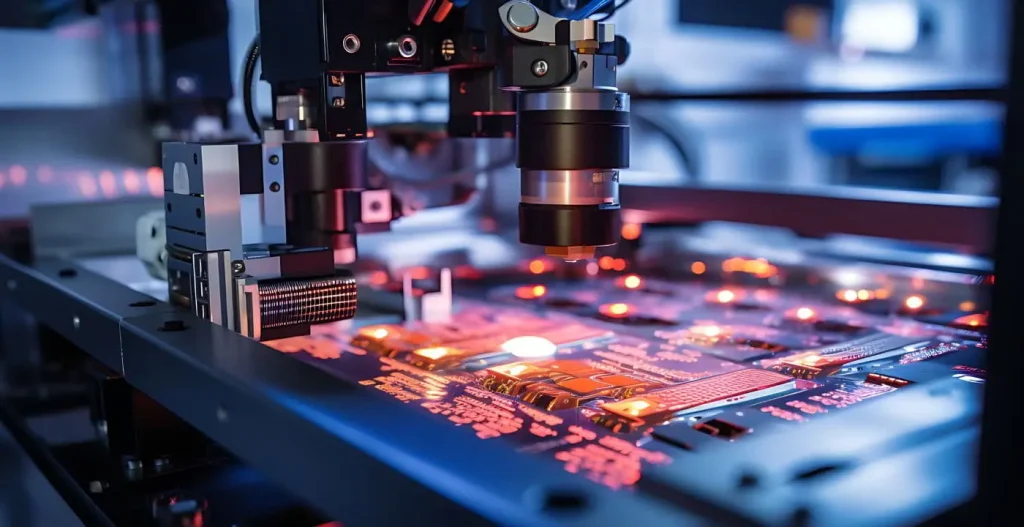

3. Optimize Air Pressure and Flow with Precision Regulators

- Improve System Efficiency: Precision regulators help maintain consistent air pressure and flow within your automation system, preventing fluctuations that can affect performance. By ensuring that air pressure is optimized for each component, you can enhance overall system efficiency and reduce energy consumption.

- Reduce Wear and Tear: Proper regulation of air pressure can minimize stress on pneumatic components, leading to reduced wear and extended equipment life. This also helps in preventing system failures and costly repairs.

Example: Installing precision regulators at key points in your automation system can stabilize air pressure for pneumatic cylinders and valves, ensuring consistent operation and reducing the risk of performance issues.

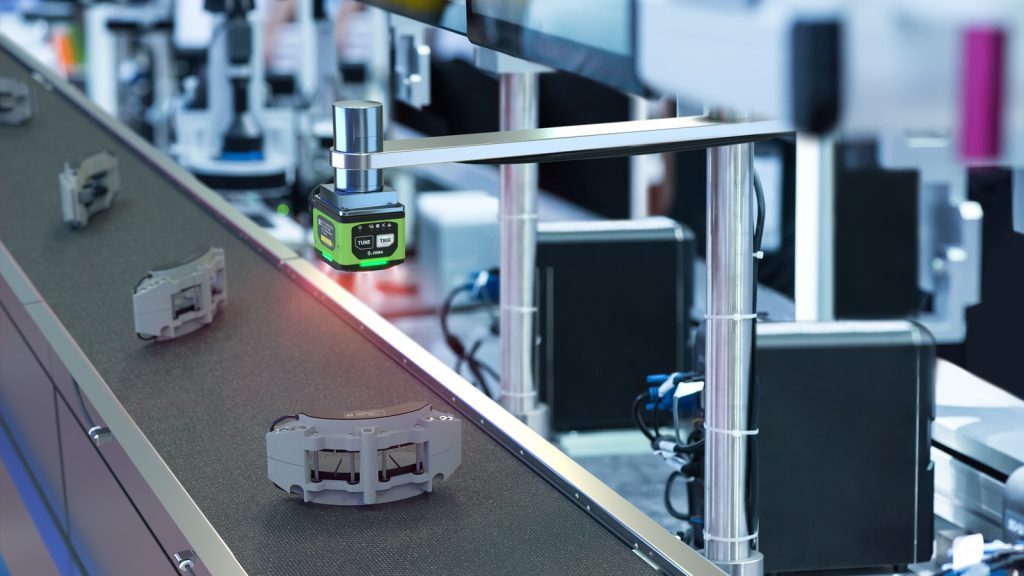

4. Utilize Pneumatic Sensors for Real-Time Monitoring

- Enhanced Diagnostics: Pneumatic sensors can provide real-time monitoring and diagnostics of your automation system, offering valuable insights into the performance of pneumatic components. Sensors can detect issues such as air leaks, pressure drops, and component malfunctions, allowing for proactive maintenance and quick resolution of problems.

- Data-Driven Decisions: By integrating pneumatic sensors with your control system, you can collect data on system performance and usage patterns. This data can be used to make informed decisions about optimizing your system, scheduling maintenance, and improving overall efficiency.

Example: Implementing pressure sensors and flow meters in your pneumatic system can help monitor performance metrics and identify potential issues before they impact operations.

5. Enhance System Flexibility with Modular Pneumatic Components

- Scalable Solutions: Modular pneumatic components, such as modular cylinders, valves, and fittings, offer flexibility and scalability for your automation system. These components can be easily reconfigured or expanded to accommodate changing production requirements or new processes.

- Simplified Maintenance: Modular designs simplify maintenance and replacement, as components can be quickly swapped out or adjusted without requiring extensive downtime or reconfiguration of the entire system.

Example: Using modular pneumatic cylinders and valve manifolds allows for easy reconfiguration of your automation system to adapt to new production lines or changes in product specifications.

Improving your automation system with pneumatic technologies can lead to significant enhancements in performance, efficiency, and flexibility. By upgrading to advanced actuators, implementing pneumatic conveying systems, optimizing air pressure with precision regulators, utilizing sensors for real-time monitoring, and adopting modular components, you can achieve a more effective and streamlined automation process. At Pneumation.ca, we are committed to helping you optimize your automation systems with high-quality pneumatic solutions and expert support. For more information or assistance with your automation needs, contact us today.