Automation Solutions for Food Processing & Packaging

Canada’s food processing and packaging industry, valued at $112.4 billion, is a key economic driver, home to some of the world’s largest food companies. Our vendors’ products play a critical role, in addressing essential food safety and efficiency standards. With our advanced electric and pneumatic food processing automation and packaging automation solutions, we deliver reliable, high-quality industrial automation tailored to meet industry demands.

Humphrey Automation is proud to be the official distributor in Canada for Food Process & Packaging automation products, providing cutting-edge solutions for optimized production.

The right Automation solutions for Food Processing & Packaging

- Beverage Industry

- Industrial Packaging

- Dairy Processing Automation

- Food Safety

- Food Automation

- Automated Bakery Solutions & More

Featured Automation Products for Food Processing & Packaging

Pisco

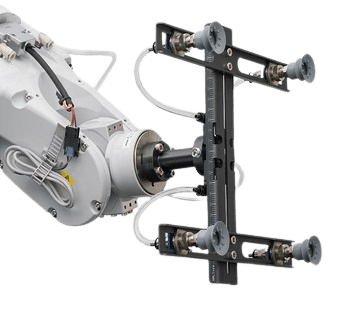

Vacuum Modular Kit HML for End of Arm Tooling EOAT

Pisco

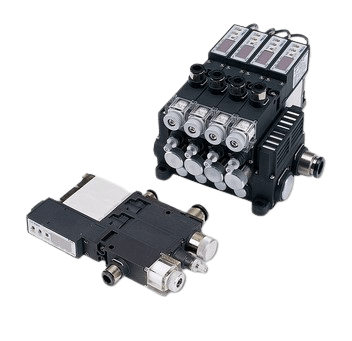

Multi function vacuum generator module VK

Koganei

High Frequency AC Ionizer – Anti Static

Koganei

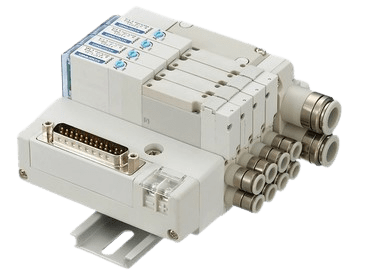

Koganei F Series Indirect Acting Solenoid Valves

Interested in purchasing or learning more about our products?

Further Uses Cases Automation in Food Processing & Packaging

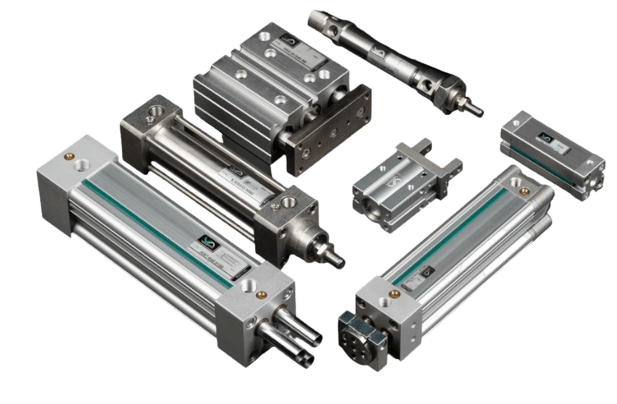

01. Pneumatic Components & Systems

In a beverage production line, ensuring that bottles are capped securely and consistently is vital. Using Koganei’s Air Grippers, which can be tailored to fit various bottle shapes and sizes, the capping process can be automated. This would involve integrated sensors to detect the position of the bottle and to apply the correct amount of pressure to secure the cap without damaging the bottle or affecting the seal’s integrity.

In meat and cheese packaging units, extending product shelf life is paramount. Here, Humphrey Products’ Vacuum Ejectors could be a pivotal element. These ejectors would be installed in the packaging line to create a vacuum environment in the packaging, eliminating air and therefore reducing the rate of spoilage. By incorporating automated sensors, the system could adjust the vacuum level based on the specific type of food being packaged, optimizing the process for different products.

The products are prepared and placed on the packaging line, ready to be packed. The end-of-arm tooling equipped with PISCO’s vacuum cups picks up the individual products gently but with a firm grip to position them accurately on the packaging trays. These vacuum cups can adapt to various product shapes and sizes, ensuring a secure grip without damaging the product.

In confectionery manufacturing units, placing delicate products like chocolates into packaging without damage is essential. Utilizing Koganei’s compact cylinders, robots can be developed with the necessary precision and gentle handling capabilities to pick and place these items without causing any breakages or deformities.

In a beverage manufacturing unit, labeling bottles accurately and efficiently is a critical step in the production line. Implementing Koganei’s rotary actuators in labeling machines can ensure that labels are applied smoothly and accurately, at high speeds, reducing downtime and enhancing productivity.

02. Electrical Motion Systems

In meat processing plants, consistent slicing of products is essential. Incorporating RTA stepper motors into slicing machines allows for precision control over the speed and depth of the cuts, ensuring uniform slices each time. The adjustable settings allow for customization according to different meat types and desired slice thicknesses, reducing product waste and enhancing efficiency.

In larger food manufacturing facilities, handling heavy loads efficiently is crucial. RTA electric linear actuators can be implemented in palletizing robots to lift and stack heavy goods with precision. These actuators provide smooth and controlled motion, reducing the risk of damage during the palletizing process, thereby safeguarding product quality until shipping.

In various food production lines, maintaining a consistent flow of products is necessary. Incorporating RTA drives in conveyor belt systems would allow for precise speed control, ensuring a uniform product flow and preventing bottlenecks or jams on the production line, thereby promoting a smoother, more efficient process.

In facilities packing varying products, flexibility is a must. By using RTA electric linear actuators in packaging robots, these systems can adapt to different packaging types and sizes quickly, reducing the time needed for manual adjustments and thereby increasing overall production speed.

In food packaging lines, a robotic arm is frequently used for pick-and-place operations to transfer products from the processing line to the packaging area. Using RTA stepper motors in these robotic arms can enhance the precision and efficiency of the pick-and-place process. The motors can control the movement of the arm with great accuracy, ensuring swift and safe transfer of products, even when dealing with fragile items like eggs or delicate pastries, minimizing the risk of product damage and maintaining a fast yet gentle operation.

03. Machine Vision Systems

Machine builders can integrate the Inspekto S70 into robotic pick-and-place systems to ensure the accuracy of product placement on assembly lines. The S70 could offer real-time feedback on the alignment and positioning of food items, helping to correct errors instantaneously and maintain a steady, uninterrupted production flow.

In automated packaging lines, machine builders can employ the Inspekto S70 to inspect the quality and condition of the packaging materials before the packaging process commences. By detecting defects such as tears or impurities, the S70 helps to prevent contaminated or compromised products from reaching consumers.

Machine builders can install the Inspekto S70 in bottling lines to monitor the volume of liquids being bottled, as well as the correct application and sealing of caps. The system can identify issues such as underfills, overfills, or improper sealing, allowing for immediate correction and minimizing wastage.

Machines involved in tray and thermoform packaging can integrate the Inspekto S70 to oversee the quality and integrity of the packaging. The system can inspect for uniformity in the thermoforming process, detect any punctures or tears in the packaging material, and verify the correct sealing, ensuring the product is adequately protected and presented in a consistent manner.

Want to know more about our custom solutions process?

Automation and Motion Control Solutions for Food and Packaging

Optimize your operations with food processing automation equipment and industrial packaging automation. Our tailored motion control solutions ensure precision, efficiency, and superior quality.