s industries worldwide shift towards more sustainable practices, the pneumatic sector is no exception. With increasing emphasis on energy efficiency, waste reduction, and environmental responsibility, sustainability in pneumatics is becoming a critical focus. Pneumatic systems are integral to countless industrial processes, and advancements in this area are driving significant progress in green manufacturing. At Pneumation.ca, we are committed to leading the charge in sustainable pneumatic solutions, helping businesses achieve their environmental goals while maintaining top performance.

The Role of Pneumatics in Green Manufacturing

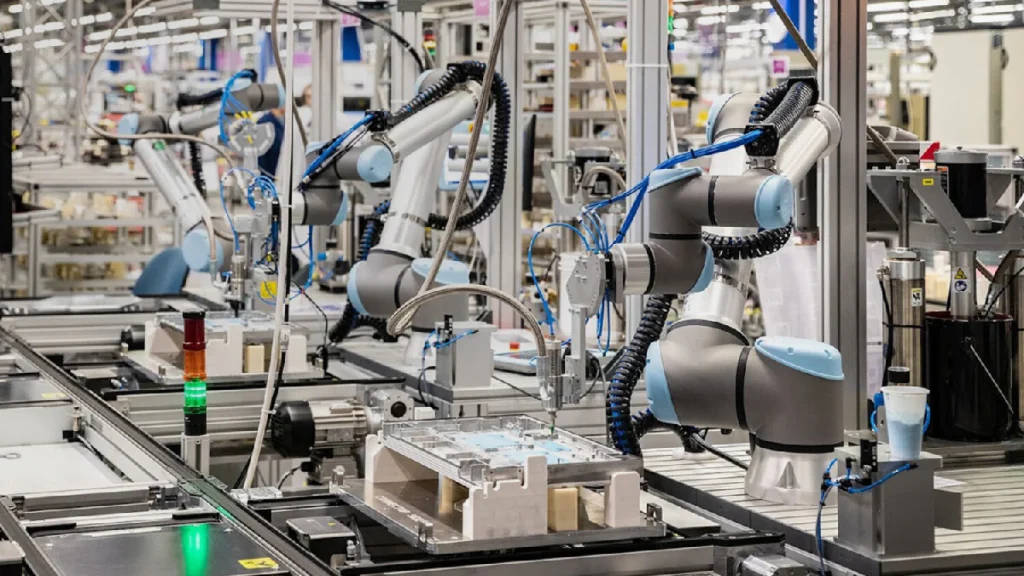

Pneumatic systems are widely used in manufacturing due to their reliability, efficiency, and versatility. However, traditional pneumatic systems can consume large amounts of energy and generate waste. The push towards sustainability in manufacturing is prompting a re-evaluation of these systems, with a focus on making them more environmentally friendly. This shift is not just about compliance with regulations; it’s about embracing a new paradigm where efficiency and sustainability go hand in hand.

Trends Shaping Sustainable Pneumatics

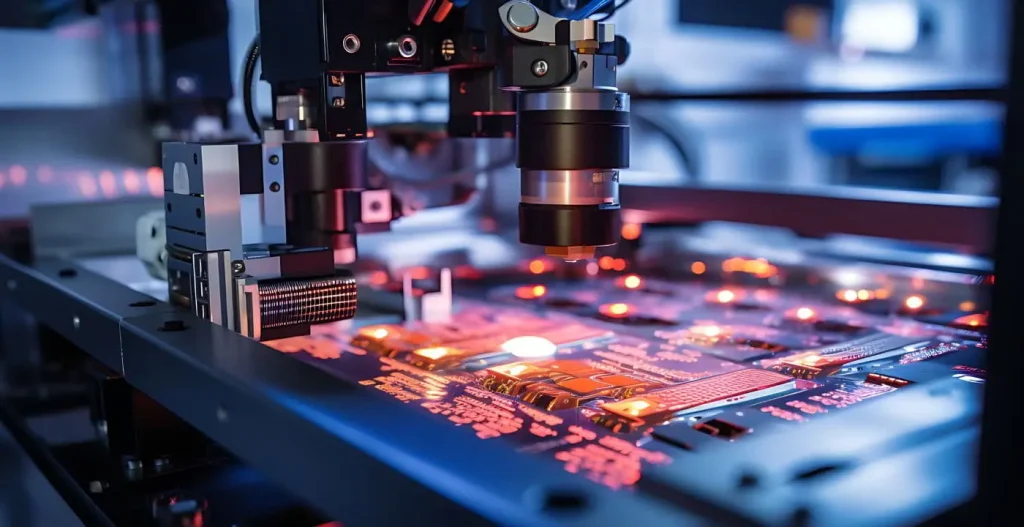

- Energy-Efficient Components

- The development of energy-efficient pneumatic components is one of the most significant trends in sustainable manufacturing. Innovations such as variable speed drives, energy recovery systems, and high-efficiency compressors are reducing the energy consumption of pneumatic systems. These advancements not only lower operational costs but also reduce the carbon footprint of manufacturing processes. At Pneumation.ca, we offer a range of energy-efficient pneumatic products designed to help businesses minimize their environmental impact.

- Smart Energy Management

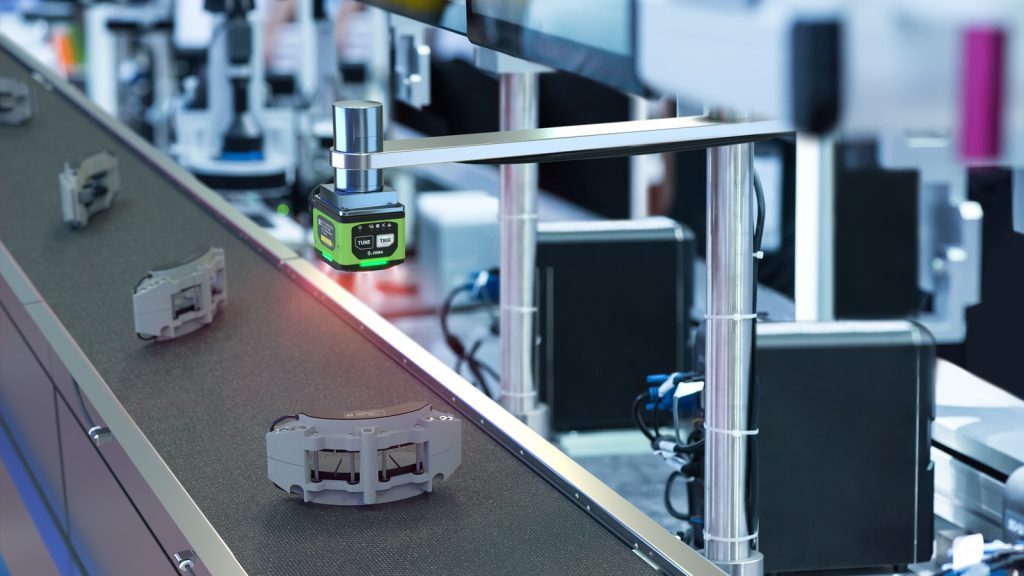

- Integrating smart technology into pneumatic systems allows for better energy management. By using sensors and IoT technology, companies can monitor and optimize energy usage in real-time. For example, smart controllers can adjust air pressure and flow rates based on demand, ensuring that no energy is wasted. This level of control leads to more sustainable operations and is a key trend driving the future of green pneumatics.

- Biodegradable and Recyclable Materials

- The use of biodegradable and recyclable materials in pneumatic components is another trend shaping sustainable manufacturing. Traditional materials used in pneumatics can be harmful to the environment if not properly disposed of. By switching to eco-friendly materials, manufacturers can reduce their environmental impact. For instance, biodegradable lubricants and recyclable seals are becoming increasingly popular in pneumatic systems, aligning with broader sustainability goals.

- Waste Reduction and Recycling

- Pneumatic systems are being designed to reduce waste and promote recycling. For example, systems that recover and reuse exhaust air are gaining traction. These systems capture waste air and redirect it back into the process, minimizing waste and reducing the need for fresh air intake. Additionally, recycling programs for old pneumatic components are becoming more common, ensuring that these parts are properly disposed of or repurposed.

- Compliance with Environmental Regulations

- As environmental regulations become stricter, compliance is driving innovation in sustainable pneumatics. Manufacturers are increasingly adopting best practices to meet or exceed these regulations. This includes not only using energy-efficient and eco-friendly components but also implementing comprehensive environmental management systems. At Pneumation.ca, we help our clients stay ahead of regulatory changes by providing solutions that align with the latest environmental standards.

The Future of Sustainable Pneumatics

The future of pneumatics lies in sustainability. As the demand for greener manufacturing practices grows, the pneumatic industry will continue to innovate, developing solutions that are both efficient and environmentally responsible. At Pneumation.ca, we are dedicated to supporting this transition, offering products and services that help our customers build a more sustainable future.

Sustainability in pneumatics is more than just a trend—it’s a fundamental shift in how the industry operates. By embracing energy-efficient components, smart energy management, and eco-friendly materials, businesses can significantly reduce their environmental impact while maintaining high levels of productivity. At Pneumation.ca, we are proud to be at the forefront of this movement, providing sustainable pneumatic solutions that shape the future of green manufacturing.