Designing an effective pneumatic control system is essential for optimizing automation processes, ensuring reliable operation, and achieving efficient performance. Pneumatic systems are used in various industries to automate machinery, control processes, and handle materials. At Pneumation.ca, we offer expertise and high-quality components to help you design a robust pneumatic control system. This article outlines best practices for designing a pneumatic control system to meet your operational needs and enhance overall efficiency.

1. Define System Requirements

- Understand Application Needs: Begin by thoroughly understanding the specific needs of your application. Identify the types of processes you need to control, the required speed and force, and the environmental conditions. This will help you determine the appropriate components and system specifications.

- Set Performance Goals: Define clear performance goals for your pneumatic system, such as desired cycle times, precision levels, and reliability standards. This will guide the selection of components and system design.

Example: For a pick-and-place application, define the required speed and force for the actuators, the type of material being handled, and the cycle time to ensure efficient and accurate operation.

2. Select the Right Components

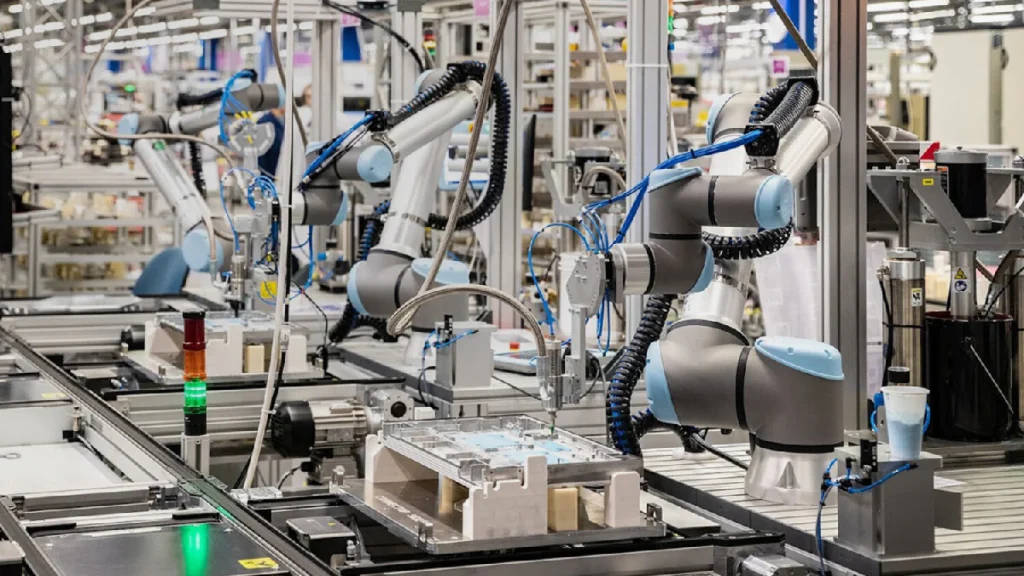

- Choose Appropriate Actuators: Select pneumatic actuators that match the required motion type (linear or rotary), force, and speed. Consider factors such as cylinder bore size, stroke length, and actuator type (single-acting or double-acting).

- Specify Valves and Regulators: Choose valves that provide the necessary control and flow rates for your application. Precision regulators help maintain consistent pressure and prevent fluctuations that can impact performance.

Example: Use double-acting cylinders for applications requiring motion in both directions and select proportional valves for precise control of air flow and pressure.

3. Design a Robust Control Circuit

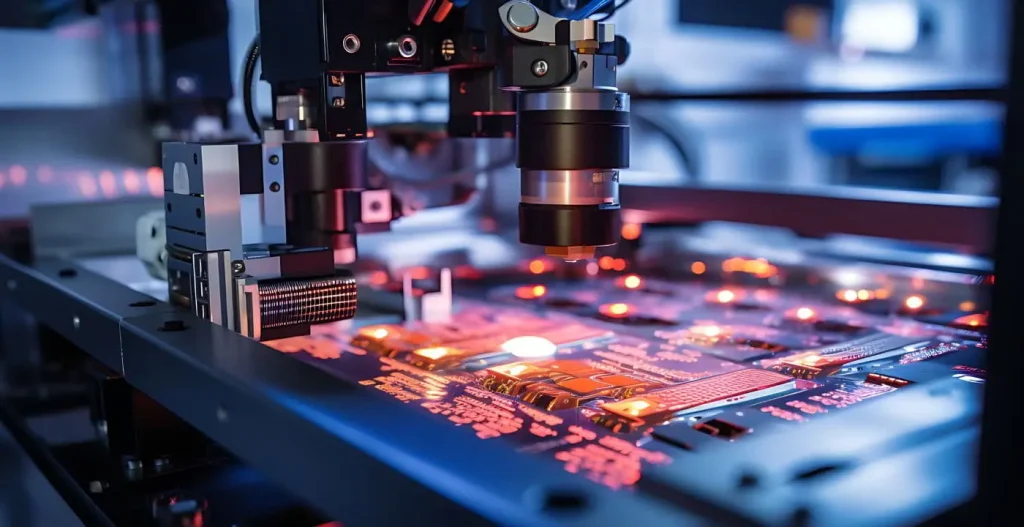

- Create a Control Diagram: Develop a detailed control circuit diagram that shows the connections between pneumatic components, such as actuators, valves, regulators, and sensors. This diagram will serve as a reference for assembly and troubleshooting.

- Incorporate Safety Features: Include safety features in your control circuit, such as emergency stop valves, pressure relief valves, and safety interlocks, to protect both equipment and personnel.

Example: Design a control circuit with a central control valve to manage air distribution and integrate safety features like exhaust valves to safely release pressure during emergencies.

4. Optimize Air Supply and Distribution

- Ensure Proper Air Supply: Provide a stable and adequate compressed air supply for your system. Size the air compressor and storage tanks based on the total air demand of the system to avoid pressure drops and ensure consistent performance.

- Design Efficient Piping: Design the distribution piping to minimize pressure drops and turbulence. Use appropriately sized pipes and avoid sharp bends that can restrict airflow. Incorporate air filters and dryers to maintain clean and dry air.

Example: Use larger diameter pipes for high-flow applications to reduce pressure drops and ensure consistent air delivery to all components.

5. Implement Monitoring and Control Systems

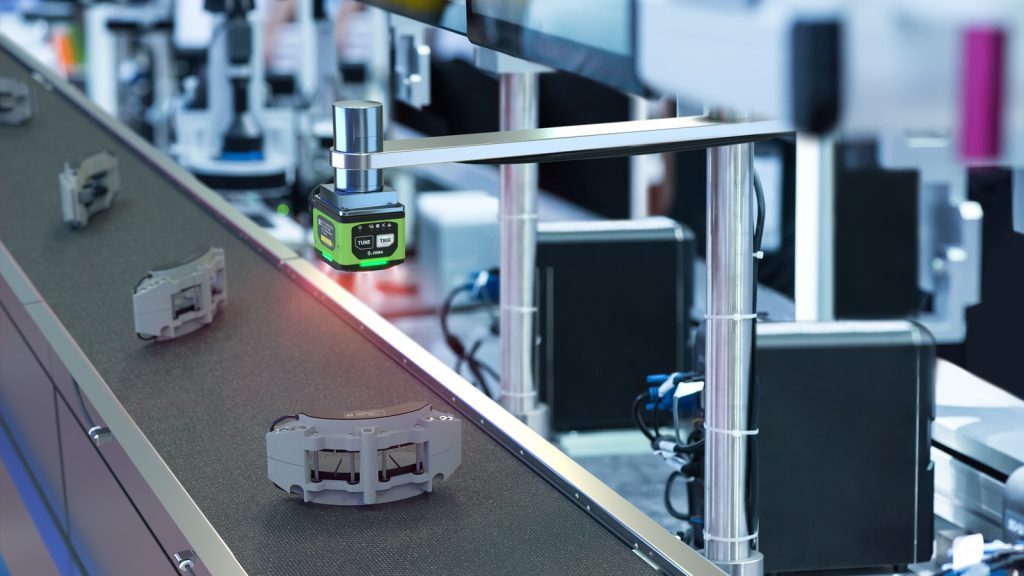

- Use Sensors for Real-Time Monitoring: Integrate sensors to monitor key parameters such as pressure, flow, and temperature. Real-time monitoring allows for early detection of issues and ensures the system operates within specified parameters.

- Incorporate Automated Controls: Implement automated control systems, such as PLCs (Programmable Logic Controllers), to manage the operation of pneumatic components. Automated controls improve precision and consistency while reducing manual intervention.

Example: Install pressure sensors to monitor the air pressure in real-time and use a PLC to automate the control of actuators and valves based on sensor inputs.

6. Plan for Maintenance and Accessibility

- Design for Easy Maintenance: Ensure that components are easily accessible for routine maintenance and inspections. Design the system layout to facilitate easy replacement of parts and troubleshooting.

- Implement Preventive Maintenance: Establish a preventive maintenance schedule to regularly check and service components. This includes inspecting for leaks, cleaning filters, and replacing worn parts to prevent unexpected failures.

Example: Design the control panel with removable covers and include clear labeling for components to simplify maintenance and troubleshooting tasks.

7. Test and Validate the System

- Conduct System Testing: Before full-scale deployment, perform thorough testing of the pneumatic control system to validate its performance against the defined requirements. Test for functionality, reliability, and safety to ensure the system operates as expected.

- Adjust and Optimize: Based on test results, make necessary adjustments to optimize system performance. This may involve fine-tuning pressure settings, adjusting flow rates, or reconfiguring components.

Example: Run a series of tests to verify that the actuators operate within the specified speed and force parameters, and adjust valve settings to achieve the desired performance.

Designing an effective pneumatic control system requires careful planning, component selection, and attention to detail. By defining system requirements, selecting the right components, designing a robust control circuit, optimizing air supply and distribution, implementing monitoring systems, planning for maintenance, and testing thoroughly, you can create a reliable and efficient pneumatic system. At Pneumation.ca, we are dedicated to providing the expertise and high-quality components you need for successful pneumatic system design. For more information or assistance, contact us today.