Pneumatic cylinders are integral to many industrial and automation systems, providing the power to move and actuate various components with precision and reliability. At Pneumation.ca, we are excited to unveil our latest models of pneumatic cylinders, which incorporate cutting-edge technologies and improvements to enhance performance, efficiency, and versatility. This article explores the new features and innovations in our latest pneumatic cylinders, showcasing how they can benefit your applications and systems.

1. What Are Pneumatic Cylinders?

- Definition and Function: Pneumatic cylinders are devices that use compressed air to produce linear motion. They convert the energy from compressed air into mechanical force to move a piston back and forth within a cylindrical chamber.

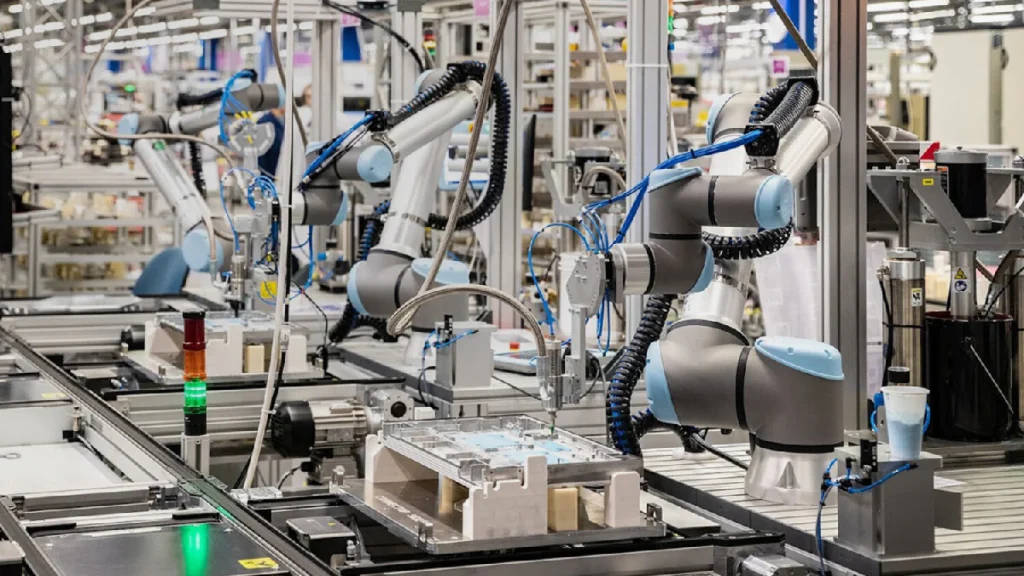

- Basic Operation: Compressed air is supplied to one side of the piston, causing it to move and perform work. The movement of the piston is then used to drive mechanical components, such as grippers, levers, or conveyors.

Example: In an automated assembly line, a pneumatic cylinder might be used to extend and retract a robotic arm to pick up and place components.

2. Key Features of Our Latest Pneumatic Cylinders

- Enhanced Durability and Reliability: Our new models feature robust construction and high-quality materials designed to withstand harsh industrial environments. This includes improved seals and bearings for longer service life and reduced maintenance.

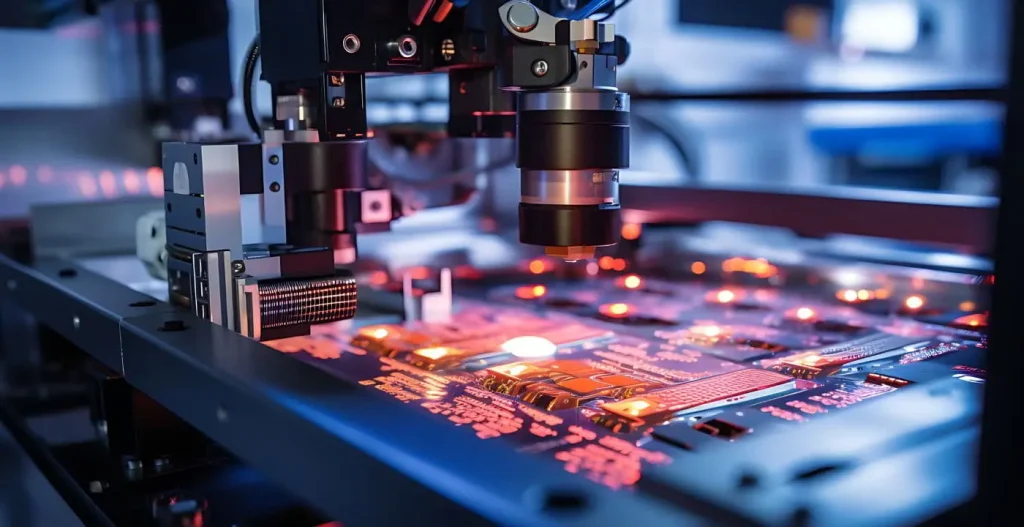

- Improved Performance: The latest cylinders offer enhanced performance characteristics, including higher speed capabilities, greater force output, and more precise control of movement. This is achieved through advanced design and manufacturing techniques.

- Compact and Lightweight Design: New designs are more compact and lightweight, making them easier to integrate into tight spaces and reducing the overall weight of your automation systems.

- Advanced Control Options: Our latest cylinders come with advanced control options, such as integrated sensors for position feedback, allowing for more precise control and automation.

Example: The new pneumatic cylinders feature improved seals and bearings, which enhance their durability and performance in high-cycle applications.

3. Benefits of Upgrading to Our Latest Pneumatic Cylinders

- Increased Efficiency: Enhanced performance and control options lead to more efficient operation, reducing energy consumption and improving overall system productivity.

- Reduced Downtime: Improved durability and reliability result in fewer breakdowns and maintenance requirements, contributing to reduced downtime and lower operational costs.

- Enhanced Precision: Advanced control features and precise movement capabilities allow for more accurate and reliable operation, improving the quality and consistency of your automated processes.

Example: Upgrading to our latest pneumatic cylinders can lead to smoother operation and higher throughput in a production line, thanks to their enhanced efficiency and precision.

4. Applications of Our Latest Pneumatic Cylinders

- Manufacturing and Assembly: Ideal for use in manufacturing and assembly lines where precise and reliable linear motion is required for tasks such as positioning, clamping, and actuation.

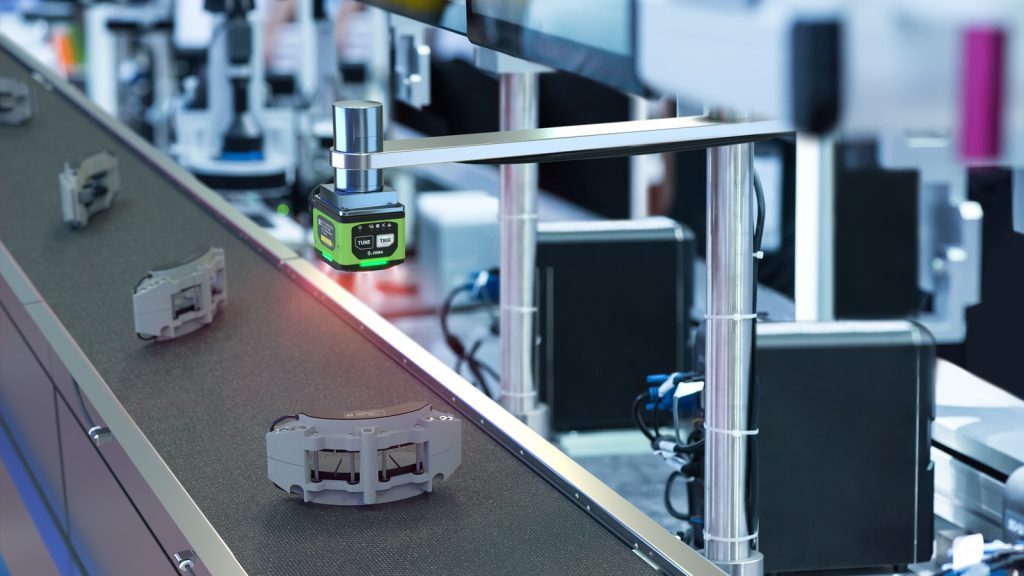

- Packaging and Material Handling: Effective in packaging systems and material handling processes, where cylinders are used to move, sort, and package products efficiently.

- Automotive and Aerospace: Suitable for applications in automotive and aerospace industries, where high performance and reliability are essential for critical systems and processes.

Example: In a packaging line, our new pneumatic cylinders can be used to automate the process of sealing and labeling boxes with greater speed and accuracy.

5. How to Choose the Right Pneumatic Cylinder

- Determine Application Requirements: Consider the specific requirements of your application, including stroke length, force output, speed, and operating environment.

- Select the Appropriate Model: Choose a pneumatic cylinder model that matches your application needs, taking into account factors such as size, weight, and control options.

- Consult with Experts: For complex applications, consult with our experts at Pneumation.ca to ensure you select the most suitable cylinder model and configuration for your needs.

Example: If you need a pneumatic cylinder for a high-speed application with precise control requirements, our team can help you select a model with the right specifications and advanced control features.

6. Installation and Maintenance Tips

- Proper Installation: Ensure that the pneumatic cylinder is installed according to the manufacturer’s guidelines, with proper alignment and secure mounting. Incorrect installation can affect performance and longevity.

- Regular Maintenance: Perform regular maintenance to check for wear, leaks, and proper operation. Follow the manufacturer’s recommendations for cleaning, lubrication, and inspection.

- Monitor Performance: Use sensors and monitoring systems to keep track of the cylinder’s performance and address any issues promptly to ensure optimal operation.

Example: Regularly inspect the seals and bearings of the pneumatic cylinder to prevent leaks and maintain smooth operation, following the maintenance schedule provided by Pneumation.ca.

7. Future Trends in Pneumatic Cylinder Technology

- Integration with Smart Technologies: Future developments may include greater integration with smart technologies, such as IoT and AI, allowing for real-time monitoring, diagnostics, and adaptive control.

- Development of Energy-Efficient Designs: Expect to see more focus on designing energy-efficient pneumatic cylinders that reduce energy consumption and environmental impact.

- Enhanced Customization Options: There will be continued advancements in customizable features and configurations, enabling more tailored solutions for diverse applications.

Example: Future pneumatic cylinders may include advanced sensor systems for real-time feedback and adjustment, enhancing their adaptability and efficiency in dynamic environments.

Our latest range of pneumatic cylinders represents a significant advancement in technology, offering enhanced durability, performance, and control options. By upgrading to our new models, you can achieve greater efficiency, reliability, and precision in your pneumatic systems. At Pneumation.ca, we are committed to providing top-quality pneumatic components and expert support to meet your needs. For more information about our latest pneumatic cylinders or assistance with your automation systems, contact us today.