Pneumatic actuators are pivotal components in automation and industrial systems, translating compressed air into mechanical motion to perform a wide range of tasks. At Pneumation.ca, we are thrilled to introduce our next-generation pneumatic actuators, which represent a leap forward in technology and performance. This article provides an overview of these innovative actuators, their advanced features, and the benefits they bring to various applications.

1. What Are Pneumatic Actuators?

- Definition and Function: Pneumatic actuators use compressed air to produce linear or rotary motion. They convert the energy from compressed air into mechanical work, enabling the movement of parts or components within a system.

- Types of Pneumatic Actuators: Common types include linear actuators, which provide straight-line motion, and rotary actuators, which deliver rotational movement. Each type serves different purposes based on application requirements.

Example: In an automated assembly line, a pneumatic linear actuator might be used to extend and retract a robotic arm, while a rotary actuator might be employed to rotate components or tools.

2. Key Features of Our Next-Generation Pneumatic Actuators

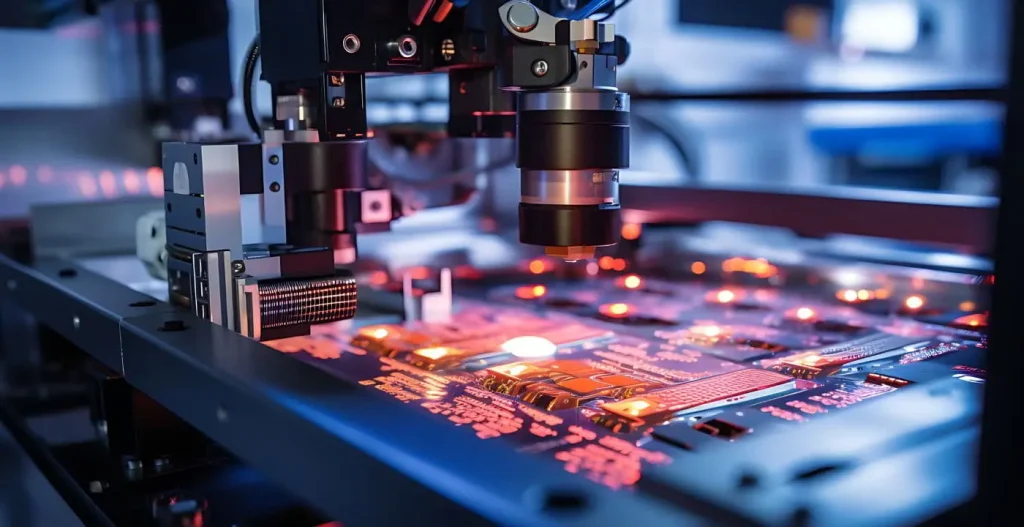

- Advanced Performance: Our latest actuators feature enhanced performance characteristics, including improved speed, force, and precision. This results in more efficient and accurate operation across a range of applications.

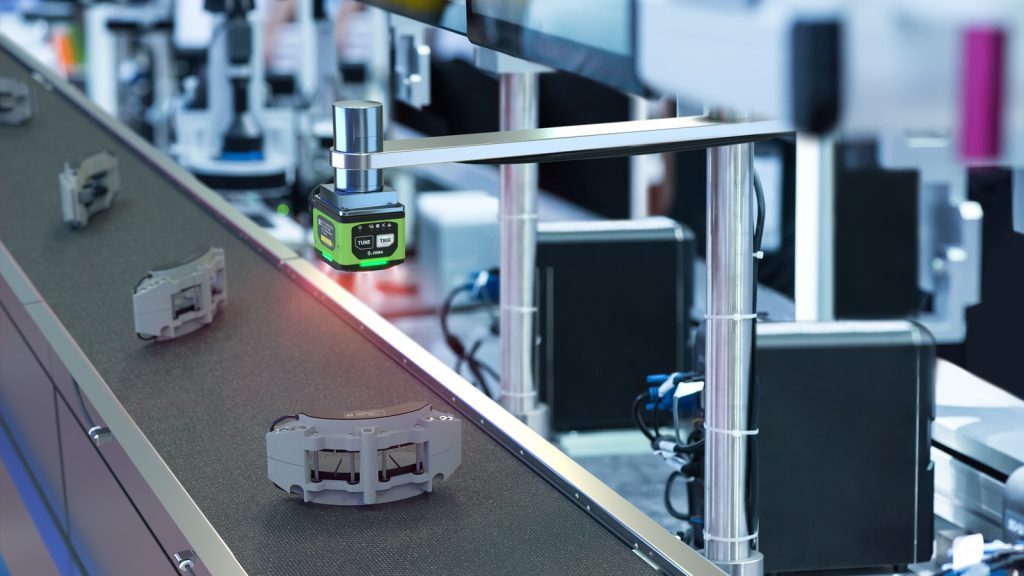

- Integrated Sensors: The new actuators come with integrated sensors that provide real-time feedback on position, force, and other parameters. This allows for more precise control and monitoring.

- Compact and Lightweight Design: Designed to be more compact and lightweight, these actuators are easier to integrate into tight spaces and reduce the overall weight of your automation systems.

- Durability and Reliability: Built with high-quality materials and advanced engineering, our actuators are highly durable and reliable, even in demanding industrial environments.

- Energy Efficiency: The next-generation actuators are designed to be more energy-efficient, reducing overall energy consumption and operational costs.

Example: Our new linear actuators feature integrated sensors that provide real-time position feedback, allowing for precise adjustments and enhanced control in automated processes.

3. Benefits of Next-Generation Pneumatic Actuators

- Improved Efficiency: Enhanced performance and energy efficiency lead to reduced operational costs and increased productivity. The actuators operate more efficiently, minimizing energy waste and maximizing output.

- Greater Precision: Integrated sensors and advanced control features provide more precise and accurate motion control, improving the quality and consistency of your automated processes.

- Enhanced Durability: The robust construction and high-quality materials ensure longer service life and reduced maintenance needs, contributing to greater reliability and lower downtime.

- Versatility: The compact and lightweight design allows for greater flexibility in system integration, making it easier to adapt the actuators to a variety of applications.

Example: By incorporating our next-generation pneumatic actuators into a packaging system, you can achieve higher throughput and better precision, resulting in improved overall efficiency.

4. Applications of Our Next-Generation Pneumatic Actuators

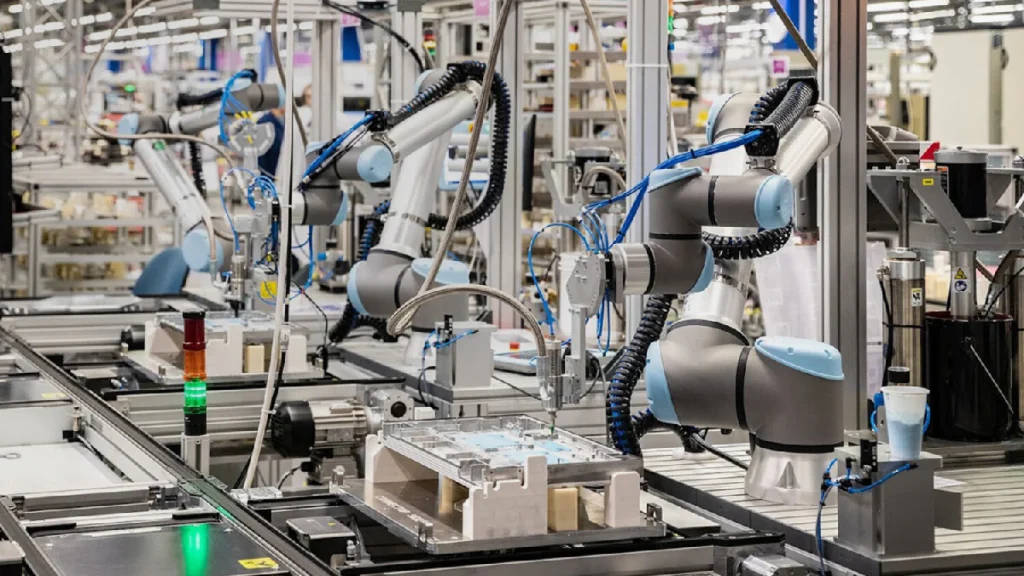

- Manufacturing and Assembly: Ideal for use in manufacturing and assembly processes where precise and reliable motion control is required for tasks such as positioning, clamping, and material handling.

- Packaging and Automation: Effective in packaging systems and automated processes where high-speed and accurate actuation are crucial for sorting, sealing, and labeling.

- Robotic Systems: Suitable for integration into robotic systems, providing reliable and precise motion control for tasks such as gripping, positioning, and assembly.

Example: In a robotic assembly application, our next-generation pneumatic actuators can be used to control the movement of robotic arms, enhancing precision and efficiency in complex assembly tasks.

5. How to Choose the Right Pneumatic Actuator

- Define Application Needs: Determine the specific requirements of your application, including motion type (linear or rotary), force, speed, and operating environment.

- Select the Appropriate Model: Choose a pneumatic actuator model that meets your application needs, considering factors such as size, weight, and control features.

- Consult with Experts: For complex applications, consult with our experts at Pneumation.ca to ensure you select the most suitable actuator model and configuration for your system.

Example: If your application requires high-speed linear motion with precise control, our team can help you select an actuator with the right specifications and integrated sensors.

6. Installation and Maintenance Tips

- Proper Installation: Follow the manufacturer’s guidelines for installing the pneumatic actuator, ensuring correct alignment and secure mounting. Proper installation is crucial for optimal performance and longevity.

- Regular Maintenance: Perform regular maintenance to check for wear, leaks, and proper operation. Adhere to the manufacturer’s recommendations for cleaning, lubrication, and inspection.

- Monitor Performance: Use integrated sensors and monitoring systems to track the actuator’s performance and address any issues promptly to maintain optimal operation.

Example: Regularly inspect and calibrate the sensors on the pneumatic actuator to ensure accurate position feedback and smooth operation.

7. Future Trends in Pneumatic Actuator Technology

- Integration with Smart Technologies: Expect to see increased integration with smart technologies, including IoT and AI, allowing for real-time monitoring, diagnostics, and adaptive control based on data inputs.

- Development of Advanced Materials: Future advancements may involve the use of advanced materials to improve actuator performance, durability, and energy efficiency.

- Customizable Solutions: There will be continued focus on providing customizable pneumatic actuators tailored to specific application needs, offering greater flexibility and adaptability.

Example: Future pneumatic actuators may feature advanced AI-driven controls that adapt their operation based on real-time data, enhancing performance and efficiency in dynamic environments.

Our next-generation pneumatic actuators represent a major advancement in technology, offering enhanced performance, precision, and energy efficiency. By upgrading to these new models, you can achieve greater efficiency, reliability, and flexibility in your automation systems. At Pneumation.ca, we are committed to providing top-quality pneumatic components and expert support to meet your needs. For more information about our next-generation pneumatic actuators or assistance with your automation systems, contact us today.