Compressed air filtration systems are essential for maintaining the quality and reliability of pneumatic systems by removing contaminants from compressed air. At Pneumation.ca, we are proud to introduce our latest innovations in compressed air filtration systems, designed to enhance performance, efficiency, and reliability. This article explores these new advancements, their features, and how they can improve your compressed air systems.

1. Importance of Compressed Air Filtration

- Definition and Purpose: Compressed air filtration systems remove impurities such as dust, moisture, and oil from compressed air. This is crucial for preventing damage to pneumatic components, ensuring optimal performance, and maintaining the quality of the final product.

- Types of Contaminants: Common contaminants include particulate matter, water vapor, and oil aerosols. Each type requires different filtration methods to effectively remove impurities and protect the system.

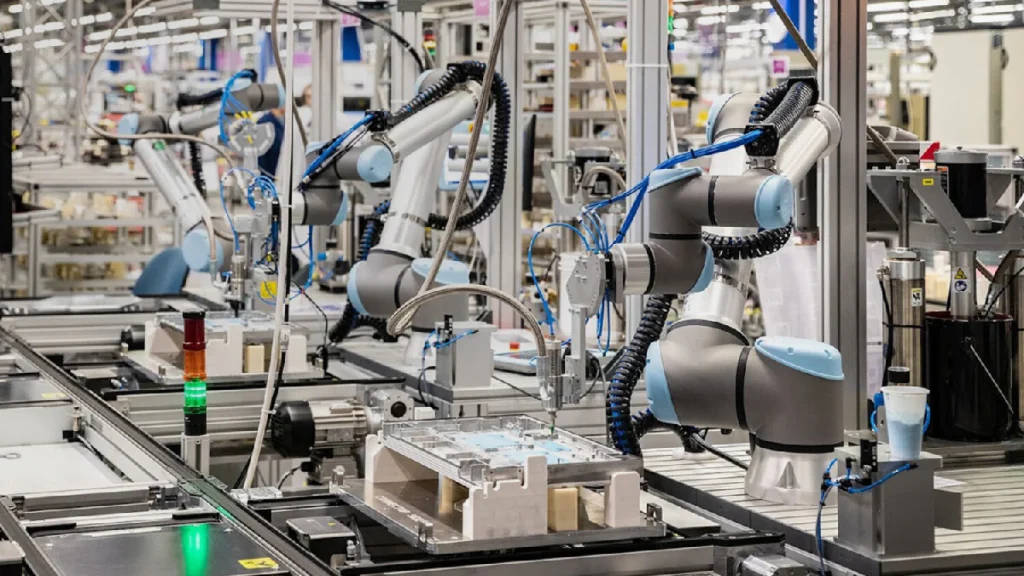

Example: In a manufacturing facility, high-quality compressed air is essential for the operation of precision tools and machinery. Effective filtration prevents contamination that could lead to equipment failure and product defects.

2. Key Features of Our Latest Compressed Air Filtration Systems

- Advanced Filtration Technology: Our new systems utilize cutting-edge filtration technology to provide superior contaminant removal. This includes multi-stage filters and high-efficiency coalescing filters that capture a wide range of particles and aerosols.

- Enhanced Efficiency: The latest filtration systems offer improved efficiency with lower pressure drops and reduced energy consumption. This results in lower operational costs and improved overall system performance.

- Modular Design: The innovative modular design allows for easy expansion and customization of the filtration system to meet specific application needs. This flexibility ensures that the system can be adapted as requirements change.

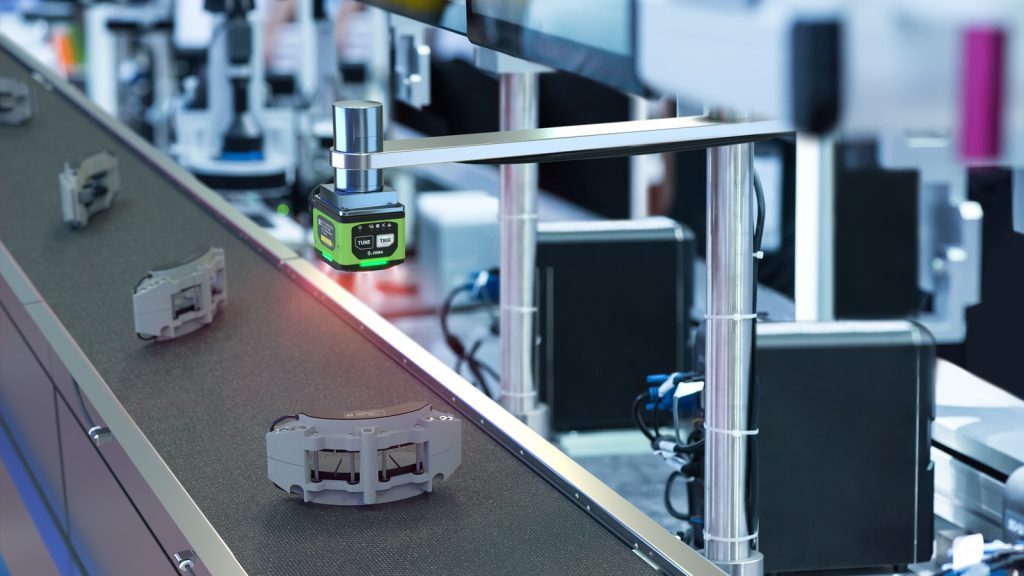

- Real-Time Monitoring: Equipped with real-time monitoring capabilities, our filtration systems provide continuous feedback on filter performance and system health. This enables proactive maintenance and ensures optimal operation.

- Durability and Reliability: Built with high-quality materials and robust construction, our filtration systems are designed to withstand demanding industrial environments, providing long-lasting performance and reliability.

Example: The new multi-stage filters in our systems offer enhanced contaminant removal, ensuring cleaner compressed air and extending the life of pneumatic components.

3. Benefits of Our Latest Compressed Air Filtration Systems

- Improved Air Quality: Advanced filtration technology ensures cleaner compressed air by effectively removing contaminants. This leads to better performance and longevity of pneumatic components.

- Cost Savings: Enhanced efficiency and reduced pressure drops result in lower energy consumption and operational costs. The modular design also allows for cost-effective system expansion.

- Reduced Downtime: Real-time monitoring and proactive maintenance capabilities help identify and address issues before they lead to system failures, reducing downtime and maintenance costs.

- Enhanced System Performance: Cleaner compressed air improves the overall performance and reliability of pneumatic systems, leading to better quality products and fewer disruptions in operations.

Example: By upgrading to our latest filtration systems, you can achieve significant cost savings and improved system reliability in a high-demand manufacturing environment.

4. Applications of Advanced Compressed Air Filtration Systems

- Manufacturing and Production: Ideal for use in manufacturing and production environments where high-quality compressed air is required for precision machinery and processes.

- Food and Beverage: Essential for the food and beverage industry, where clean compressed air is crucial for maintaining product quality and hygiene standards.

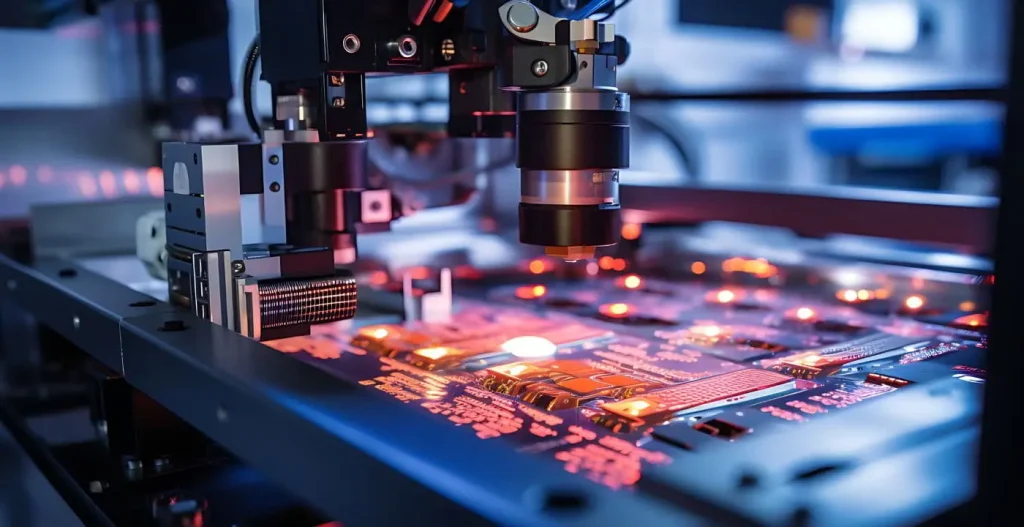

- Pharmaceuticals and Biotechnology: Critical for the pharmaceuticals and biotechnology industries, where stringent air quality standards are necessary for ensuring product safety and effectiveness.

Example: In the pharmaceutical industry, our advanced filtration systems ensure that compressed air used in production processes meets strict quality standards, preventing contamination and ensuring product safety.

5. How to Choose the Right Compressed Air Filtration System

- Assess Contaminant Levels: Evaluate the types and levels of contaminants present in your compressed air to determine the filtration requirements.

- Consider System Requirements: Take into account factors such as flow rate, pressure, and space constraints when selecting a filtration system.

- Consult with Experts: For tailored recommendations, consult with our experts at Pneumation.ca to ensure you choose a filtration system that meets your specific needs and application requirements.

Example: Our team can help you select the appropriate filtration system based on your facility’s specific contaminant levels and operational needs, ensuring optimal performance and efficiency.

6. Installation and Maintenance Tips

- Proper Installation: Follow the manufacturer’s guidelines for installation to ensure correct setup and optimal performance. Pay attention to factors such as filter orientation and connection points.

- Regular Maintenance: Perform routine maintenance, including filter replacement and system checks, to ensure continued effectiveness and reliability.

- Monitor System Performance: Utilize real-time monitoring features to track filter performance and address any issues promptly to maintain system efficiency.

Example: Regularly check and replace filters according to the manufacturer’s recommendations to ensure continuous high-quality filtration and prevent system disruptions.

7. Future Trends in Compressed Air Filtration Technology

- Integration with IoT: Future advancements may include greater integration with IoT technologies, allowing for more sophisticated monitoring, diagnostics, and remote management capabilities.

- Development of Advanced Filter Materials: Expect to see innovations in filter materials that offer even higher efficiency and longer service life, reducing maintenance needs and operational costs.

- Enhanced Customization: There will be a focus on providing more customizable filtration solutions to meet diverse application requirements and adapt to changing industry standards.

Example: Future filtration systems may incorporate smart technology to automatically adjust filtration parameters based on real-time data, enhancing adaptability and efficiency.

Our latest innovations in compressed air filtration systems represent a significant advancement in technology, offering enhanced efficiency, real-time monitoring, and superior contaminant removal. By upgrading to our advanced filtration solutions, you can improve air quality, reduce costs, and enhance the performance and reliability of your pneumatic systems. At Pneumation.ca, we are dedicated to providing top-quality filtration systems and expert support to meet your needs. For more information about our latest innovations in compressed air filtration or assistance with your systems, contact us today.