Agriculture & Agritech Automation Solutions

With 2.3 million people employed, Canada’s agriculture and agritech industry is a cornerstone of the economy. Humphrey Automation is driving transformation with advanced agriculture automation solutions, innovative machine vision systems, and cutting-edge pneumatic and electric technologies. From sowing to harvesting, we deliver automation in the agriculture industry to optimize efficiency and precision, paving the way for the future of farm automation.

Humphrey Automation is proud to be the official distributor in Canada for agriculture and agritech automation solutions, offering innovative solutions for modern farming.

The right Automation solutions for Agriculture Industry

- Sorting Machines

- Robotic Harvesters

- Fertilizer Spreaders

- Seed Planters

- Automated Feeding Systems

- Agri-Photovoltaics Systems

Featured Automation Products for Agriculture & Agritech

Humphrey Products

Balanced Solenoid Valves

IP67

AirTac

NFPA NSU Series Cylinders

AirTac

FRL Series

RTA

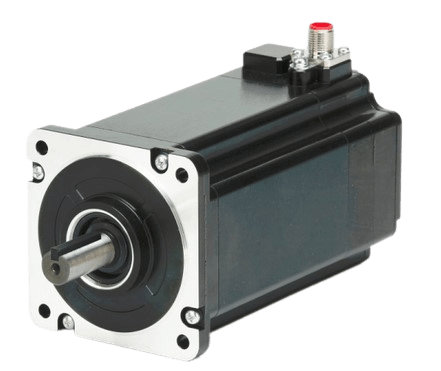

IP 65 Industrial Stepping Motors

Interested in purchasing or learning more about our products?

Further Uses Cases Automation in Agriculture & Agritech

01. Pneumatic Components and Equipment

Pneumatic seed planters have revolutionized precision agriculture by enabling automated and accurate seed placement. A crucial component in such a setup could be Airtac’s ISO 15552 standard cylinders which are known for their durability and precision. These cylinders could facilitate a seamless seed release mechanism, ensuring uniform depth and spacing. Meanwhile, Pisco’s UR Polyurethane tubing could be implemented in the pneumatic circuit to guarantee optimal airflow, thus ensuring the precise release and placement of seeds, contributing to a more abundant and uniform crop yield.

Post-harvest, preserving the quality of hay or straw becomes a priority. Here, automated bale wrappers equipped with Koganei’s F Series pneumatic cylinders can provide the required force to wrap bales securely. These cylinders are known for their smooth operation and reliability, enhancing the wrapping process. Integrating Humphrey Products’ 310/410 solenoid valves into the system could enable better control over the air pressure and flow, thereby ensuring a consistent and tight wrap which is vital to preserve the quality of the harvested material.

For state-of-the-art grain handling facilities, the efficiency and reliability of grain transport systems are paramount. Incorporating Pisco’s vacuum generators can provide a powerful and steady suction force, essential in the smooth conveyance of grains over significant distances, reducing potential loss and contamination risks. A seamless integration with Aignep’s Infinity piping system could help in establishing a robust pneumatic network, ensuring a stable and controlled flow of materials, especially crucial during peak harvesting seasons.

Gentle and precise harvesting of fragile fruits is now achievable with robotic harvesters equipped with pneumatic grippers. Implementing Aignep’s 500 series grippers into these systems would allow for a delicate yet firm grasp on fruits, preventing damage during the picking process. Further integration with Koganei’s miniature shock absorbers can ensure a smooth operation, minimizing impact forces and thereby preserving the quality of the harvest, promoting higher yield and quality.

I hope this expansion with specific product suggestions provides a comprehensive view of how these items can be synergized in various agricultural applications.

02. Electrical Motion Systems

Emerging as a potent tool in sustainable agriculture, precision weed removal systems employ sophisticated machine vision algorithms to differentiate between crops and weeds. Utilizing RTA’s servo motors for actuating the robotic arms can offer incredibly precise control, allowing for quick and accurate removal of weeds without harming the adjacent crops. This technique minimizes the need for chemical weed control, promoting a more organic farming approach.

Automated harvesting systems have been revolutionized with the integration of smart technology. Incorporating RTA’s stepper motors into these systems can enhance the efficiency and precision of harvesting operations. The motors can drive harvesting tools with high precision, enabling the careful and selective harvesting of crops at the optimum ripeness, thereby reducing waste and improving yield quality.

In modern agritech, high-throughput phenotyping platforms are emerging as a crucial tool for crop improvement. Utilizing RTA’s drives to control conveyor systems can facilitate the smooth transition of plant samples through various imaging stations. These platforms can analyze plant traits rapidly and accurately, aiding in the development of new crop varieties with desirable characteristics.

Robotic pruning systems are gaining traction as a method to maintain the health and productivity of perennial crops. Incorporating RTA’s servo motors in these systems can provide the high level of control needed to perform precise cuts. Coupled with machine vision technology, these systems can identify the optimal pruning points, promoting healthier growth and higher yields in the long run.

Automated greenhouses represent the convergence of technology and agriculture. Employing RTA’s drives in controlling various aspects of the greenhouse environment, such as ventilation systems or automated shading screens, can create optimal growing conditions. These drives can modulate the operation of various devices based on sensor data, promoting optimal growth while minimizing energy usage.

03. Machine Vision Systems

Agritech is increasingly employing drones for various applications like crop monitoring and aerial spraying. Ensuring the reliability of drone components is vital for successful operations. The Inspekto S70 can be used to inspect various drone components such as propellers, motors, and sensors. It can detect issues like cracks in propellers or malfunctions in sensors, preventing potential failures during flight. This helps in ensuring the drones can perform their tasks reliably, providing accurate data and effective solutions for crop management.

By integrating the Inspekto S70 into the inspection processes for various mechanical parts and hardware systems in agriculture and agritech, industries can enhance the reliability and performance of their equipment, fostering more efficient and productive operations.

Harvesting equipment like combines and mowers have blades and cutting elements that need to be in top-notch condition to function efficiently. The Inspekto S70 can be utilized to inspect these blades for signs of wear, cracks, or deformities. For instance, it can assess the sharpness and alignment of combine harvester blades, ensuring that they can cut crops cleanly without causing damage. This helps in maintaining the performance of the harvesting equipment, resulting in smoother operations during the harvest season.

In the manufacturing of agricultural machinery like tractors, maintaining the quality of each component is crucial. The Inspekto S70 can be employed on the production line to inspect various tractor components such as gears, shafts, and bearings. With its advanced image processing capabilities, it can detect defects like cracks, chips, or incorrect dimensions, ensuring that only components meeting the quality standards are used. This helps in building durable and reliable machinery, reducing the risk of breakdowns in the field.

Irrigation systems consist of various components such as sprinklers, drip lines, and pumps, which need regular inspections to function efficiently. The Inspekto S70 can be used to inspect these components for signs of wear and tear or malfunctions. For instance, it can analyze high-resolution images of sprinkler heads to detect clogs or damage, ensuring uniform water distribution and avoiding wastage. This proactive approach helps in maintaining the irrigation systems in optimal condition, ensuring a consistent water supply for crops.

Want to know more about our custom solutions process?

Automation and Motion Control Solutions for Agriculture & Agritech

As the official distributor in Canada, we provide advanced automation and motion control solutions for agritech, optimizing farming with precision and efficiency.