Automation Solutions for Defence Industry

Canada’s defense industry is vital to national security and global innovation, leading in advanced military systems. With high-precision pneumatic and electrical motion equipment, Humphrey Automation supports defense automation, delivering tailored solutions for the rigorous demands of the defense industry. Our commitment to quality fuels innovation, reinforcing Canada’s leadership in defense technology and ensuring the safety of its citizens.

Humphrey Automation is proud to be the official distributor in Canada for automation solutions in the defense industry, offering cutting-edge technologies for mission-critical applications.

The right Automation solutions for your military-ready system

- Autonomous Defense Platforms

- Tactical Robotics

- Radar and Communication

- Missile Systems

- Armored Vehicle

- Unmanned Aerial Vehicles

Featured Automation Products for Defence Industry

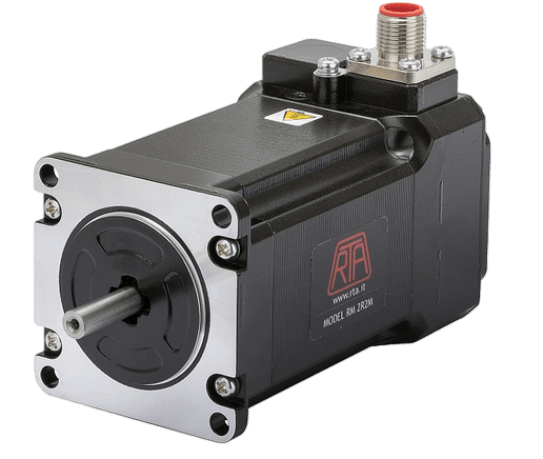

RTA

Heavy Duty Motors

Mavilor

Military Applications Servo Systems

Pisco

Cable Carriers

Humphrey Products

310 & 410 Direct Acting Reliable Solenoid Valves

Interested in purchasing or learning more about our products?

Further Uses Cases and Potential Defence Applications

01. Pneumatic Components and Equipment

In military aviation, oxygen generation systems are vital for maintaining the safety and performance of pilots operating at high altitudes. Pneumatics play a critical role in these systems by providing the necessary pressure and flow control to generate and deliver oxygen efficiently. Pneumatic compressors and valves regulate the oxygen supply, ensuring that pilots receive a steady and reliable flow of oxygen, which is crucial for maintaining cognitive function and physical performance in low-oxygen environments. These systems are designed to be robust and reliable, capable of functioning under the extreme conditions often encountered in combat missions, where consistent oxygen supply is a matter of life and death.

The sensitive electronic components in avionics and missile systems generate significant heat, which, if not properly managed, can lead to system failures. Pneumatic cooling systems are employed to dissipate this heat, ensuring that the equipment operates within safe temperature ranges. These systems use compressed air to circulate cool air around critical components, preventing overheating and ensuring optimal performance. In missile systems, where space is limited and components are densely packed, pneumatic cooling provides an efficient and reliable method to protect the electronics that control guidance, targeting, and detonation functions. Similarly, in avionics, pneumatic cooling systems help maintain the integrity of flight control systems, navigation equipment, and communication devices, ensuring that military aircraft can operate safely and effectively in demanding environments.

Pneumatics are integral to the operation and control of missile and weapons systems in the defense industry. In these systems, pneumatics are used to power various mechanisms, such as the deployment of missile fins, control surfaces, and launch mechanisms. For example, in missile launchers, pneumatic actuators are responsible for the precise movement required to position missiles for launch, ensuring they are correctly aligned with the target trajectory. Pneumatics also play a role in the safe handling and loading of munitions, providing the necessary force to move heavy missiles into firing position without risking damage to the weapon or its guidance systems.

Pneumatic systems are indispensable in the maintenance of military aircraft, where precision, reliability, and efficiency are paramount. Pneumatic tools are used for a variety of tasks, including tightening and loosening bolts, drilling, and cutting materials, which are critical during regular maintenance and repair operations. These tools are favored in military settings due to their lightweight, portability, and ability to operate in environments where electrical tools may not be safe or practical, such as in fuel-laden or high-moisture environments. Additionally, pneumatic systems are used in the operation of jacks and lifts that raise aircraft for undercarriage inspections and repairs, ensuring that maintenance crews can perform their tasks with speed and accuracy, thereby minimizing aircraft downtime and ensuring mission readiness.

02. Electrical Motion Systems

Electrical motion systems, particularly servo motors, are crucial in the operation of radar systems. These motors provide precise control over the movement of radar antennas, enabling them to rotate and tilt with exactitude to track targets over vast distances. Servo motors offer the high torque and rapid response needed to adjust the radar’s direction quickly, ensuring continuous monitoring and accurate detection of fast-moving objects such as aircraft or missiles. The precision of these motors is essential for the radar to maintain a steady focus on targets, even in harsh environments where stability and reliability are critical.

Unmanned systems, including drones (UAVs) and unmanned ground vehicles (UGVs), rely heavily on stepper and servo motors for a variety of functions. Servo motors are used to control the flight surfaces of drones, such as ailerons, rudders, and elevators, allowing for precise maneuvering and stability during flight. In UGVs, stepper motors provide the control needed for navigation and obstacle avoidance, enabling these vehicles to traverse complex terrains autonomously. These motors are also integral to the operation of robotic arms and payload deployment mechanisms on unmanned systems, ensuring they can perform tasks such as reconnaissance, logistics, and even weapon delivery with high accuracy and reliability.

Servo motors play a critical role in the navigation and guidance systems of missiles. These motors control the movement of fins and other control surfaces, allowing the missile to adjust its flight path in real-time to hit a moving target accurately. The precision and responsiveness of servo motors are vital for ensuring that the missile can make fine adjustments to its trajectory, especially during the terminal phase of flight, where accurate targeting is most crucial. Electrical motion systems are also used in the gimbal mechanisms that stabilize and direct onboard sensors and targeting systems, further enhancing the missile’s ability to strike its intended target with high precision.

In fire control systems for both ground-based and naval artillery, stepper and servo motors are used to adjust the positioning of gun barrels and turrets. These motors enable precise aiming adjustments, allowing the weapon system to lock onto targets with high accuracy. Servo motors provide the necessary speed and torque to move large weaponry quickly and accurately, while stepper motors allow for fine-tuned adjustments to the elevation and azimuth of the guns. This level of control is essential in dynamic combat scenarios where rapid target acquisition and accuracy are critical for mission success.

In targeting and tracking systems used in both air and ground-based defense platforms, servo motors play a crucial role in ensuring the accuracy and reliability of weapon targeting. These systems require precise and rapid adjustments to keep a moving target in sight, often in dynamic and high-pressure combat scenarios. Servo motors control the movement of optical and infrared sensors, as well as laser designators, which are used to lock onto and track targets. The motors’ high torque and precision enable the system to make fine adjustments in real-time, ensuring that the targeting reticle remains fixed on the target, even as it moves at high speeds or changes direction. This capability is essential for the effectiveness of guided munitions, allowing for accurate strikes with minimal collateral damage. Additionally, the reliability and durability of servo motors in these systems ensure consistent performance in diverse environmental conditions, from desert heat to arctic cold, making them indispensable in modern defense technology.

03. Machine Vision Systems

In the production of ammunition, the Inspekto vision system can be deployed to ensure that every round meets strict quality and safety standards. This system can inspect each cartridge for defects such as cracks, dents, or deformities that could affect performance or safety. The vision system’s high-resolution imaging and advanced AI algorithms allow it to detect even the smallest imperfections, which might be missed by human inspectors. By automating this inspection process, the Inspekto system ensures that only the highest quality ammunition is delivered to the defense forces, reducing the risk of malfunctions and enhancing the reliability of munitions in the field.

During the assembly of military vehicles, such as armored personnel carriers or tanks, the Inspekto vision system can be used to inspect critical components like engine parts, transmission systems, and chassis structures. The system can perform real-time inspections on the assembly line, checking for proper alignment, part integrity, and the presence of all required components. For example, the vision system can verify that bolts are correctly torqued, welds are clean and consistent, and that no foreign objects are present in sensitive areas. This level of scrutiny helps prevent assembly errors that could compromise the performance or safety of the vehicle in combat situations, ensuring that every vehicle meets the rigorous standards required for military operations.

In the manufacturing of avionics for military aircraft, the Inspekto vision system can be employed to inspect electronic circuit boards for defects such as soldering errors, component misplacement, or damaged traces. Given the critical role that avionics play in the operation and safety of military aircraft, it is essential that these systems are flawless. The Inspekto vision system can quickly and accurately scan each circuit board, identifying any potential issues before the boards are installed in aircraft. This early detection of defects helps prevent costly rework or failures in the field, ensuring that the avionics systems perform reliably under the demanding conditions of military aviation. By automating the inspection process, the Inspekto system also increases the efficiency of the manufacturing process, allowing for faster production without compromising on quality.

Want to know more about our custom solutions process?

Automation and Pneumatic Components and Equipment for Defence Manufacturing Industry

Optimize defense manufacturing with advanced automation and pneumatic components. Our reliable equipment ensures precision, efficiency, and innovation for the unique demands of the defense industry.