Automation for Electronics & Semiconductor Manufacturing

In the fast-paced world of Electronics and Semiconductor production, precision, speed, and adaptability are essential. Canada’s electronics and semiconductor industry, valued at nearly $4 billion, continues to grow, with companies like Celestica, Evertz Technologies, and Sierra Wireless at the forefront. At Humphrey Automation, we drive innovation with advanced electronics automation and semiconductor process automation solutions, leveraging cutting-edge machine vision systems and pneumatic and electric technologies. Achieve unmatched control, accuracy, and adaptability, elevating your production to the next level.

Humphrey Automation is the official distributor in Canada for electronics manufacturing automation products, providing state-of-the-art solutions for the industry.

The right Automation solutions for Electronics & Semiconductor Manufacturing

- Pick and Place Machines

- Component Insertion Machines

- Automatic Optical Inspection

- Robotics and Automation

- Die Bonder Machines

- Chemical Mechanical Planarization & More

Featured Automation Products for Electronics & Semiconductor

Interested in purchasing or learning more about our products?

Further Uses Cases Automation in Electronics & Semiconductor

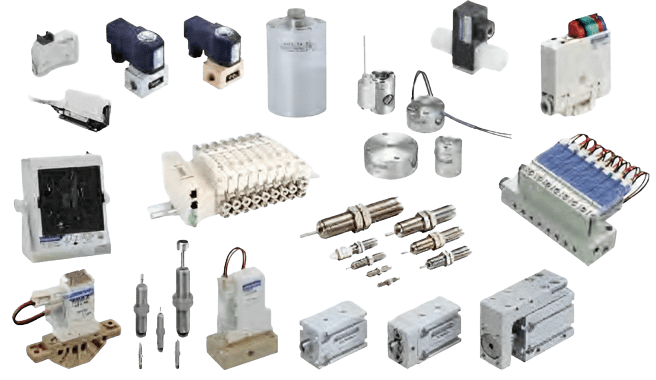

01. Pneumatic Components and Equipment

In semiconductor manufacturing, the safe and precise handling of silicon wafers is critical. Here, Airtac’s pneumatic grippers could be integrated into robotic arms to handle wafers delicately, preventing any damage while ensuring smooth transfer from one processing station to another. Utilizing Koganei’s high-speed solenoid valves can further control the gripper’s speed and pressure, ensuring a gentle grip on the fragile wafers.

During the CVD process, precise control of gas flow is paramount. Pisco’s flow controllers can be used to accurately regulate the flow of gases into the chamber, ensuring uniform deposition on the wafer surface. The setup could be coupled with Humphrey Products’ ProControl Proportional Valves for better control over the gas input, allowing for fine-tuning of the process and improving layer quality.

In ion implantation, Aignep’s high-quality filters can be used to prevent contamination in the gas lines that supply the ion source. The process would benefit from incorporating Airtac’s precision regulators, facilitating precise control over the pressure of the implanted ions, ensuring uniform doping across the wafer.

During the crucial phase of battery electrode production, an even distribution of active material slurry onto the current collectors is essential for optimizing the performance and life cycle of the batteries. In this phase, Pisco’s precision dispensing valves can play a vital role in controlling the fluid dynamics of slurry dispensation. Incorporating Airtac’s advanced pneumatic cylinders can facilitate the fine motion control needed to maintain a uniform layer of coating.

Moreover, Humphrey Products’ proportional valves could be employed to maintain a steady flow rate, ensuring a consistent application. To complement this setup, integrating Koganei’s high-precision pressure regulators would assist in maintaining optimal pressure levels throughout the process, mitigating any chances of slurry spillage or uneven distribution, therefore enhancing the quality and consistency of battery electrodes.

In battery assembly lines, the pressing of various layers to assemble a complete cell is a critical process. Here, Humphrey Products’ high-force pneumatic cylinders can be the centerpiece, exerting controlled yet powerful pressure to ensure firm and uniform bonding between the layers.

Further, integrating Aignep’s advanced pneumatic vibration dampeners can minimize vibrations during the pressing process, ensuring a smoother operation and preventing potential damage to the sensitive layers. Additionally, using Koganei’s high-speed pneumatic actuators can automate the loading and unloading of battery components, thus speeding up the entire assembly line without compromising on the quality of the assembly.

Material handling in semiconductor and battery production requires both speed and precision. Using Aignep’s durable tubes and connectors in the construction of pneumatic conveying systems can facilitate smooth transitions of materials between various stages of production.

Pairing this with Humphrey Products’ directional control valves can allow for the automated routing of materials through the system, enhancing efficiency and reducing manual intervention. Moreover, installing Pisco’s air filters in the system can prevent potential contamination of materials during transfer, ensuring the purity and quality of products as they move through various production stages.

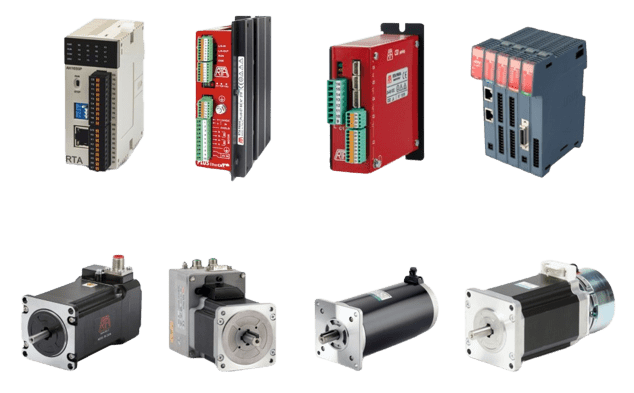

02. Electrical Motion Systems

In the delicate process of chip assembly, where components need to be placed with utmost accuracy, RTA’s servo motors can be implemented to power the robotic arms. These motors, renowned for their precision, can enable the arms to position tiny components with nanometer accuracy, thus ensuring a high yield of quality chips. The addition of RTA’s advanced drive controllers can further enhance the precision of these robotic systems, offering real-time adjustments to optimize the assembly process.

Automated Optical Inspection (AOI) is a crucial step in semiconductor manufacturing to ensure product quality and consistency. Utilizing RTA’s stepper motors in the AOI systems can enable high-speed and precise positioning of optical components, allowing for faster and more accurate inspections. These motors can be coupled with RTA’s intelligent drives for better synchronization and smoother operation, significantly reducing inspection times while enhancing accuracy.

In battery manufacturing, the uniform coating of electrodes is a critical step. Integrating RTA’s new electrical cylinders into the coating machines can provide fine control over the coating process, allowing for uniform layers and optimizing material usage. These electrical cylinders can be paired with RTA’s advanced control systems to monitor and adjust the coating parameters in real-time, ensuring a high-quality product with reduced waste.

Material handling and transportation form the backbone of semiconductor and battery manufacturing processes. Implementing RTA’s servo motors into automated guided vehicles (AGVs) can enhance their efficiency and reliability. These motors can provide AGVs with smooth, precise, and rapid movement, ensuring timely material delivery between different production stations. The integration of RTA’s drive systems can further optimize the AGV’s operation, providing seamless integration into the larger manufacturing ecosystem.

Thermal management systems are vital in semiconductor and battery manufacturing sectors to prevent overheating and maintain the optimum operating temperature. Utilizing RTA’s electrical motion components, like their high-performance fans and cooling systems powered by their efficient motors, can offer precise control over the thermal management process. Coupling these systems with RTA’s intelligent controllers can enable real-time monitoring and adjustments, ensuring optimum environmental conditions and prolonging the lifespan of critical manufacturing equipment.

In each of these use cases, RTA’s products play a critical role in optimizing various aspects of the semiconductor and battery manufacturing processes, offering enhanced precision, efficiency, and reliability.

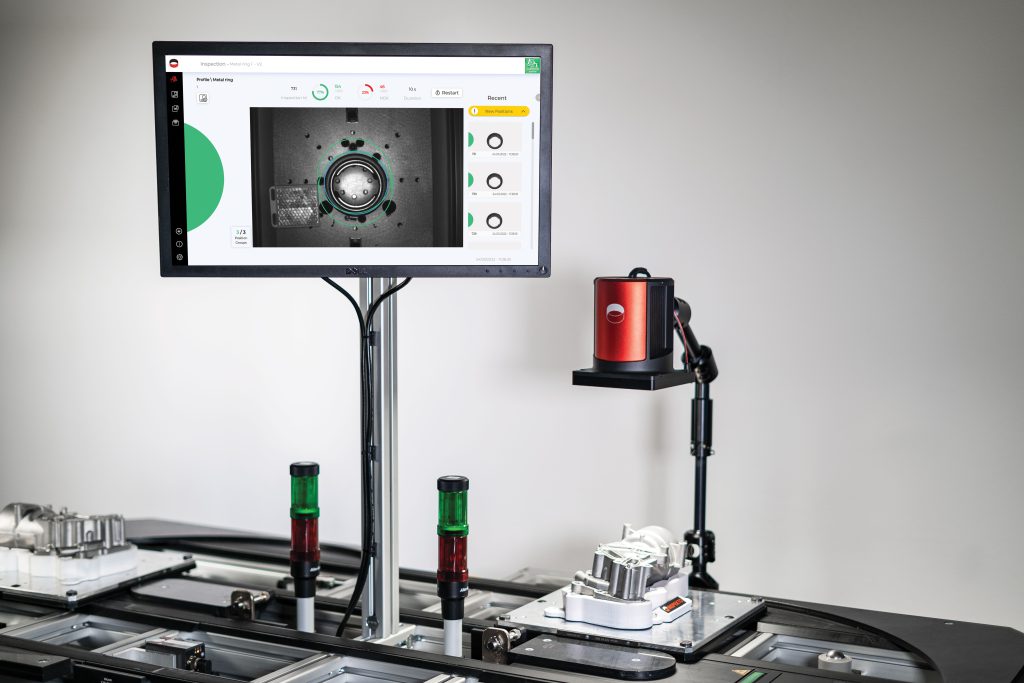

03. Machine Vision Systems

In electronics manufacturing, PCB assembly is a critical process where various components are mounted on the board. The Inspekto S70 can be a valuable tool at this stage, providing visual inspections to verify the correct placement and orientation of components. It can detect issues like misalignments, incorrect components, or missing elements early in the process, allowing for corrections before proceeding to soldering. This early detection can prevent costly rework later in the process and ensure a high quality of the final product.

In battery manufacturing, the integrity of the cell casing is critical to the safety and performance of the final product. The Inspekto S70 can be utilized to inspect the cell casings for defects such as cracks, deformations, or imperfections that might compromise the battery’s safety. With its high-resolution imaging capabilities, the system can detect even minor defects, ensuring that only casings meeting the stringent quality criteria are used in the final assembly, thus minimizing the risk of leaks or other failures in the finished batteries.

In each of these use cases, the Inspekto S70 can provide invaluable support in maintaining quality and reducing defects, leveraging its advanced visual inspection capabilities to enhance the reliability and safety of products in the semiconductor, electronics, and battery manufacturing sectors.

In the battery manufacturing industry, maintaining the uniformity of electrode layers is vital to the performance and safety of the final product. The Inspekto S70 system can be implemented at the electrode production stage to inspect the layers for uniformity and consistency. Its visual inspection capabilities can detect variations in thickness, impurities, or surface defects, ensuring that only layers meeting the stringent quality criteria are used in the assembly, hence minimizing the risk of battery failures due to defective electrode layers.

During the production of semiconductor wafers, the dies must be inspected for defects like cracks, scratches, or impurities. The Inspekto S70, with its high-resolution imaging and intelligent analysis algorithms, can be used to conduct detailed inspections of the wafer dies. It can detect even minuscule defects that might be invisible to the naked eye, ensuring that only the highest quality dies proceed to the next stage of manufacturing. It can significantly enhance the yield quality and reduce the risk of incorporating defective dies into the final product.

In electronics manufacturing, ensuring the quality of solder paste application is critical to the final product’s reliability and performance. The Inspekto S70, with its advanced visual inspection capabilities, can be integrated into the solder paste application process to inspect the paste deposits in real-time. For instance, it can verify the correct amount of paste deposition, ensuring that there are no insufficiencies or excesses which could lead to solder bridges or weak joints in later stages. The system can also verify the alignment and positioning of the paste, providing an opportunity for corrections before components are placed, thus enhancing yield and reducing waste.

Want to know more about our custom solutions process?

Electronics Manufacturing Automation Perfectly Tailored to Your Needs

Discover automation for electronics and semiconductor manufacturing tailored to your needs. Our advanced solutions deliver precision, speed, and adaptability for cutting-edge production excellence.