Automation Solutions for Energy & Natural Resources

At the core of Canada’s economic strength are its rich natural resources. From vast oil and gas reserves to the promising potential of hydrogen energy, Canada is a hub for energy evolution. Its extensive mining sector extracts valuable metals and minerals while thriving forests support a robust wood industry. Driving these industries forward is the innovative use of automation in renewable energy and energy automation solutions. From hydrogen production and storage to high-pressure, cryogenic, and high-temperature oil and gas applications, our vendors’ pneumatic and electrical motion equipment plays a critical role. Our solutions also enhance forestry and mining operations, automating key processes in the natural resources sector.

Humphrey Automation is proud to be the official distributor in Canada for energy automation solutions, offering cutting-edge technologies for sustainable progress.

The right Automation solutions for Energy & Natural Resources

- Oil & Gas

- Hydrogen

- Wood Processing

- Mining

- Fisheries

- Renewable Energy & More

Featured Automation Products for Energy & Natural Resources

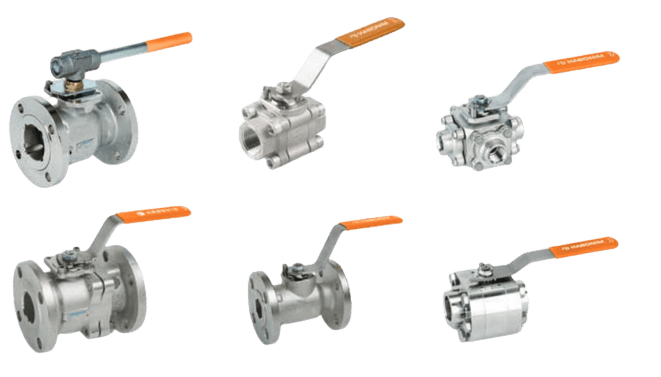

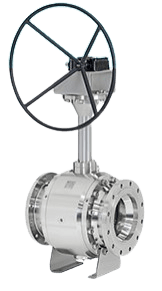

Habonim

Cryogenic Trunnion Mounted Valves Series

Interested in purchasing or learning more about our products?

Further Uses Cases in Energy & Natural Resources Equipment

01. Valves & Process Control

In the burgeoning hydrogen production industry, managing high-pressure systems is of utmost importance. Habonim’s high-pressure ball valves, known for their robustness and reliability, could be employed in these settings. The valves can control the flow of hydrogen in the system with precision, reducing chances of leaks and ensuring safety and efficiency. Coupled with Habonim’s compact actuators, they would allow for automated and remote control, enhancing both safety and operational efficiency.

When transporting hydrogen, it is often stored in a cryogenic state. Habonim’s cryogenic ball valves, designed to operate optimally in extremely low temperatures, can be utilized in these systems to control the flow of cryogenic fluids safely and effectively. These valves can be paired with Habonim’s pneumatic actuators to automate the process, ensuring a seamless and efficient operation in the hydrogen transportation infrastructure.

In geothermal plants, where high-temperature fluids are often utilized, Habonim’s metal-seated ball valves can be employed. These valves can handle the extreme temperatures encountered in geothermal energy production, maintaining a tight seal and preventing leaks. Pneumatically controlled by Habonim’s actuators, they would allow for precise control over the fluid flow, optimizing the energy production process.

In geothermal plants, where high-temperature fluids are often utilized, Habonim’s metal-seated ball valves can be employed. These valves can handle the extreme temperatures encountered in geothermal energy production, maintaining a tight seal and preventing leaks. Pneumatically controlled by Habonim’s actuators, they would allow for precise control over the fluid flow, optimizing the energy production process.

Maintaining the cleanliness of solar panels is important to maintain their efficiency. Humphrey Products’ solenoid valves and air cylinders can be used in automated solar panel cleaning systems, controlling the flow of cleaning fluids and the movement of cleaning apparatus, ensuring a thorough and efficient cleaning process.

In each of these cases, specific products from the listed companies would play crucial roles in enhancing the safety, efficiency, and reliability of various processes within the energy and natural resources sectors.

02. Electrical Motion Systems

Solar farms require precise panel alignment to efficiently capture sunlight. Utilizing RTA’s newly introduced electrical cylinders in tandem with their stepper motors, the solar panels’ orientation can be finely adjusted throughout the day to follow the sun’s path. The stepper motors can control the rotational aspects of the alignment system with great precision, while the electric cylinders can manage the linear adjustments. Together, they create a highly coordinated system capable of dynamic adjustments throughout the day, maximizing the amount of sunlight captured and thereby increasing the overall efficiency of the solar farm. This integration could lead to a substantial improvement in the energy output of solar farms, making solar energy a more viable option for meeting the world’s energy needs.

Automated waste sorting systems are becoming increasingly popular as a way to enhance recycling rates and reduce landfill waste. RTA servo motors can be utilized in these systems to control sorting mechanisms with high precision. The motors can drive conveyor belts, robotic arms, and other machinery that separate recyclable materials from general waste, ensuring a higher recovery rate of recyclable materials and promoting a more sustainable waste management approach.

In each of these cases, specific RTA products offer the reliability and precision necessary to improve efficiency and sustainability within the Energy & Natural Resources sector.

In mining operations, conveyor belts are used extensively to transport materials over long distances. Integrating RTA electric cylinders into these systems can provide precise control over belt tension and speed, ensuring smooth operation and minimizing wear and tear. These cylinders can also be used in gate mechanisms that control the flow of materials onto the belts, preventing overloading and optimizing throughput.

In fish farms, automated feeding systems are employed to ensure timely and appropriate feeding. RTA electric cylinders could be used to precisely control the delivery of fish feed, while the stepper motors can control the rotation and angle of feeding tubes, ensuring an even distribution of feed in large tanks or enclosures, ultimately improving the growth rate and health of the fish.

Modern sawmills employ sophisticated machinery to process logs efficiently. Utilizing RTA servo motors in sawmill machinery can enable precise control over the speed and positioning of saw blades, optimizing the cutting process to minimize waste and produce high-quality timber products.

Lumber yards employ loading and unloading systems to handle large quantities of lumber. Implementing RTA stepper motors into these systems can offer enhanced control over the machinery, ensuring smoother operations and reducing the risk of damage to the lumber during handling.

03. Machine Vision Systems

In the manufacturing process of solar panels, micro-cracks can occur on the solar cells, which could potentially decrease the efficiency of the panel. The Inspekto S70 can be used to detect micro-cracks in the solar cells during the production process. Its high-resolution imaging can identify even the finest cracks, allowing for immediate corrections and ensuring the highest quality in the final product.

Harvesting equipment like combines and mowers have blades and cutting elements that need to be in top-notch condition to function efficiently. The Inspekto S70 can be utilized to inspect these blades for signs of wear, cracks, or deformities. For instance, it can assess the sharpness and alignment of combine harvester blades, ensuring that they can cut crops cleanly without causing damage. This helps in maintaining the performance of the harvesting equipment, resulting in smoother operations during the harvest season.

In the manufacturing of agricultural machinery like tractors, maintaining the quality of each component is crucial. The Inspekto S70 can be employed on the production line to inspect various tractor components such as gears, shafts, and bearings. With its advanced image processing capabilities, it can detect defects like cracks, chips, or incorrect dimensions, ensuring that only components meeting the quality standards are used. This helps in building durable and reliable machinery, reducing the risk of breakdowns in the field.

Irrigation systems consist of various components such as sprinklers, drip lines, and pumps, which need regular inspections to function efficiently. The Inspekto S70 can be used to inspect these components for signs of wear and tear or malfunctions. For instance, it can analyze high-resolution images of sprinkler heads to detect clogs or damage, ensuring uniform water distribution and avoiding wastage. This proactive approach helps in maintaining the irrigation systems in optimal condition, ensuring a consistent water supply for crops.

Want to know more about our custom solutions process?

Automation and Process Control Solutions for Energy & Natural Resources Industries

Boost efficiency with our automation and process control solutions for energy and natural resources industries. Explore advanced energy automation technologies for a smarter, sustainable future.