As industries evolve, the demand for smaller, more efficient pneumatic systems is growing. Miniaturization, the process of making components and systems smaller without sacrificing performance, is a significant trend shaping the future of pneumatic technology. Compact pneumatic systems offer numerous advantages, from reduced energy consumption to enhanced versatility, making them ideal for modern manufacturing environments. At Pneumation.ca, we are at the forefront of this trend, providing advanced miniaturized pneumatic solutions that meet the needs of today’s industries.

The Need for Miniaturization in Pneumatics

Miniaturization in pneumatic systems is driven by several factors, including the need for more efficient space utilization, the push for energy conservation, and the desire for increased flexibility in system design. As manufacturing environments become more complex and space constraints more common, the ability to integrate smaller pneumatic components becomes increasingly valuable. Furthermore, miniaturized systems often consume less energy and materials, aligning with broader goals of sustainability and cost reduction.

Key Trends in Miniaturization

- Development of Micro Pneumatic Components

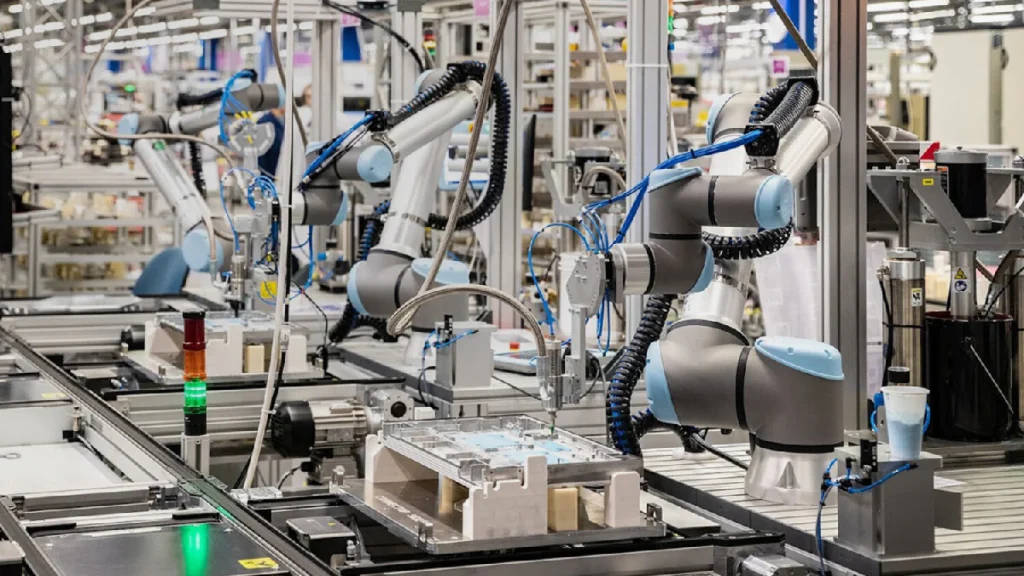

- One of the most notable trends in miniaturization is the development of micro pneumatic components. These tiny valves, actuators, and sensors are designed to perform the same functions as their larger counterparts but occupy significantly less space. Micro pneumatic components are particularly beneficial in applications where space is limited, such as in medical devices, robotics, and micro-manufacturing. At Pneumation.ca, we offer a range of micro pneumatic components that deliver high performance in a compact form.

- Integration of Multi-Functional Components

- Another trend driving miniaturization is the integration of multi-functional components. Instead of using separate components for different functions, manufacturers are increasingly developing components that can perform multiple tasks. For example, a single compact valve might combine the functions of flow control, pressure regulation, and shut-off, reducing the need for multiple parts. This not only saves space but also simplifies system design and maintenance.

- Advancements in Material Science

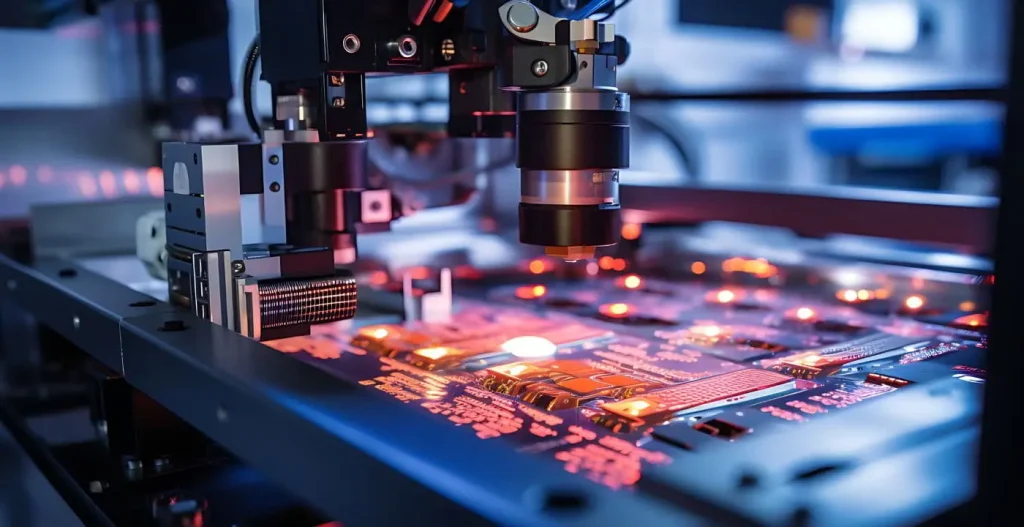

- The miniaturization of pneumatic systems is also being propelled by advancements in material science. New lightweight and durable materials are enabling the production of smaller components without compromising strength or durability. For instance, advanced polymers and composites are being used to create compact pneumatic parts that are both robust and lightweight, making them ideal for high-performance applications. These materials also contribute to reducing the overall weight of the system, enhancing its efficiency.

- Precision Manufacturing Techniques

- Precision manufacturing techniques such as micro-machining and 3D printing are playing a crucial role in the miniaturization of pneumatic systems. These techniques allow for the production of highly detailed and accurate components on a smaller scale, enabling the creation of complex pneumatic systems that are both compact and efficient. At Pneumation.ca, we utilize the latest manufacturing technologies to produce miniaturized pneumatic components that meet the highest standards of precision and quality.

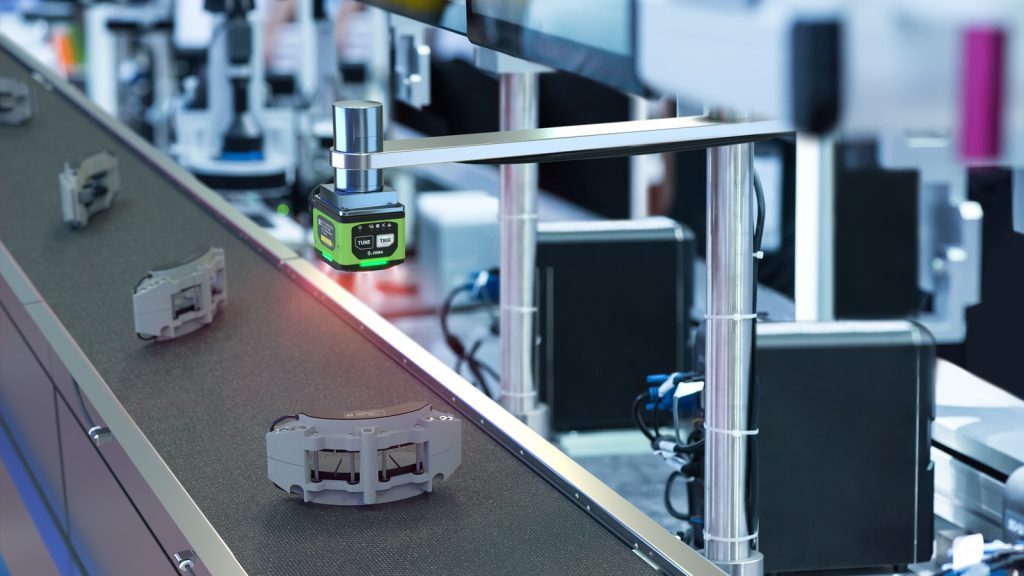

- Applications in Emerging Industries

- Miniaturized pneumatic systems are finding applications in emerging industries such as wearable technology, biotechnology, and nanotechnology. In these fields, the demand for compact, reliable, and efficient systems is paramount. For example, in medical devices, miniaturized pneumatic systems are used to control fluid flow in portable and wearable devices, offering precise control in a small footprint. The ability to integrate these systems into smaller devices is opening up new possibilities in various industries.

Challenges and Considerations

While miniaturization offers many benefits, it also presents certain challenges. Designing and manufacturing smaller components requires a high level of precision and expertise. Additionally, ensuring that miniaturized systems maintain the same level of performance and reliability as larger systems can be challenging. However, with advancements in technology and manufacturing processes, these challenges are increasingly being overcome. At Pneumation.ca, we are committed to providing our clients with miniaturized pneumatic solutions that do not compromise on quality or performance.

The Future of Miniaturized Pneumatic Systems

The trend towards miniaturization in pneumatic systems is set to continue as industries seek more compact, efficient, and versatile solutions. The future will likely see further advancements in material science, manufacturing techniques, and component integration, leading to even smaller and more powerful pneumatic systems. At Pneumation.ca, we are excited to be part of this journey, offering innovative solutions that help our customers stay ahead of the curve.

Miniaturization is transforming the pneumatic industry, offering significant benefits in terms of space efficiency, energy savings, and versatility. As this trend continues to shape the future of pneumatic systems, businesses must adapt by embracing these smaller, more efficient solutions. At Pneumation.ca, we are proud to offer cutting-edge miniaturized pneumatic components and systems that meet the demands of modern industries, helping our customers achieve greater efficiency and productivity.