Pneumatic sensors are revolutionizing the field of automation by providing precise, real-time data that enhances system performance, reliability, and efficiency. As industries increasingly rely on automation for efficiency and precision, the role of pneumatic sensors becomes more critical. At Pneumation.ca, we recognize the transformative impact of pneumatic sensors and their potential to shape the future of automation. This article explores how pneumatic sensors are influencing modern automation, their benefits, and their future potential.

1. The Role of Pneumatic Sensors in Automation

- Definition and Purpose: Pneumatic sensors measure various parameters such as pressure, flow, temperature, and position within a pneumatic system. They provide critical data that informs system control and optimization, ensuring accurate and reliable operation.

- Types of Pneumatic Sensors: Common types include pressure sensors, flow sensors, temperature sensors, and position sensors. Each type serves a specific function, contributing to the overall efficiency and performance of the system.

Example: A pressure sensor in a pneumatic system provides real-time data on air pressure, enabling precise control of actuators and valves.

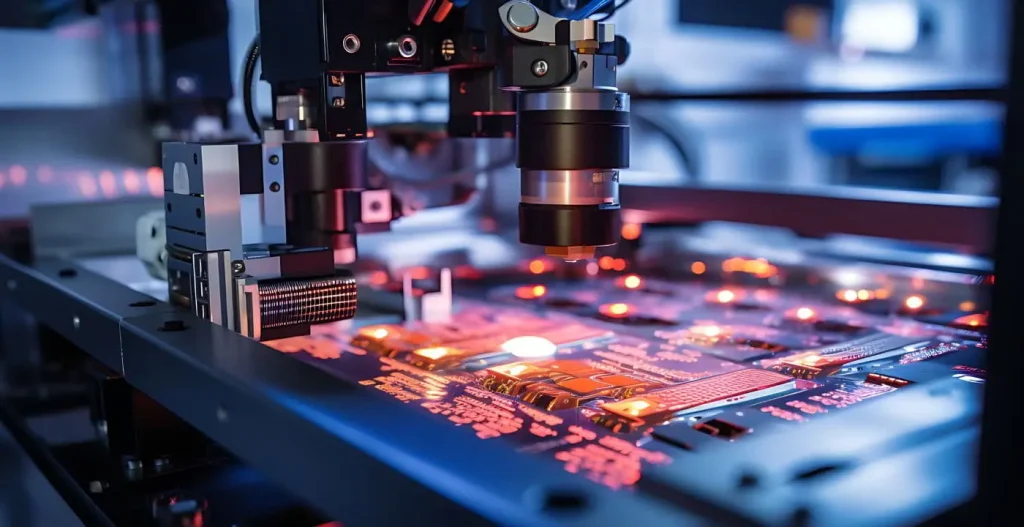

2. Enhancing Precision and Control

- Real-Time Data for Accurate Control: Pneumatic sensors deliver real-time data that allows for precise control of pneumatic components. This enhances the accuracy of operations and improves the performance of automation systems.

- Adaptive Control: Sensors enable adaptive control by providing data that allows the system to adjust its parameters based on changing conditions. This ensures optimal performance and reduces the risk of errors.

Example: In a manufacturing line, flow sensors monitor the speed of pneumatic actuators, adjusting their operation to match the production requirements and maintain consistent quality.

3. Improving System Efficiency

- Optimizing Air Consumption: Pneumatic sensors help in optimizing air consumption by monitoring and controlling the flow and pressure of compressed air. This reduces energy wastage and lowers operational costs.

- Preventing Overuse and Wear: Sensors can detect signs of inefficiency or potential issues, such as leaks or excessive wear, allowing for timely maintenance and preventing system failures.

Example: Pressure sensors can detect a drop in system pressure due to a leak, prompting maintenance actions that prevent further energy loss and maintain system efficiency.

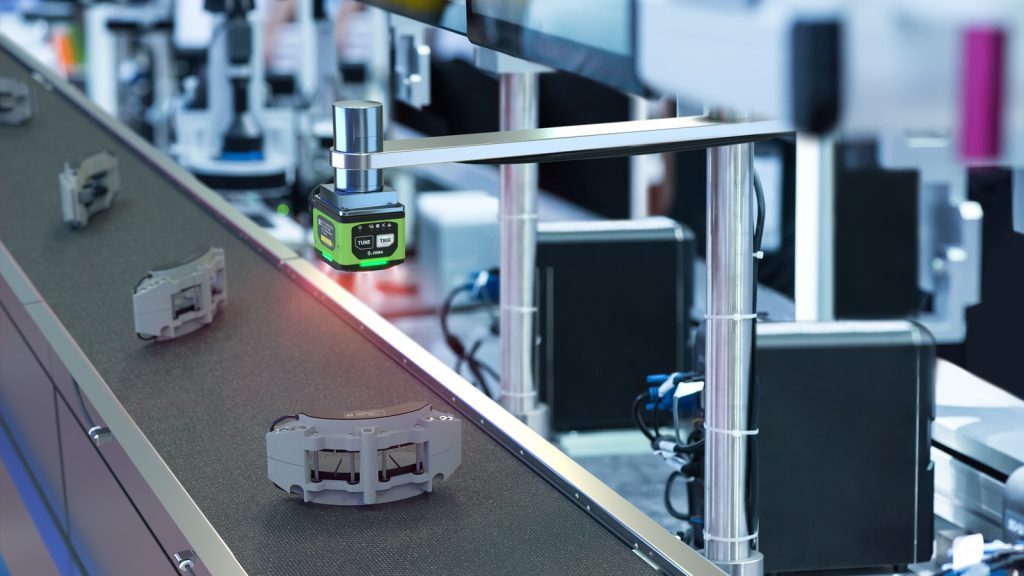

4. Enhancing Predictive Maintenance

- Data-Driven Maintenance: Pneumatic sensors provide valuable data for predictive maintenance, allowing for the early detection of potential issues before they lead to failures. This helps in scheduling maintenance activities more effectively.

- Monitoring Component Health: Sensors continuously monitor the health of pneumatic components, such as actuators and valves, providing insights into their condition and performance.

Example: Temperature sensors can indicate if an actuator is operating outside its normal temperature range, signaling the need for maintenance before a failure occurs.

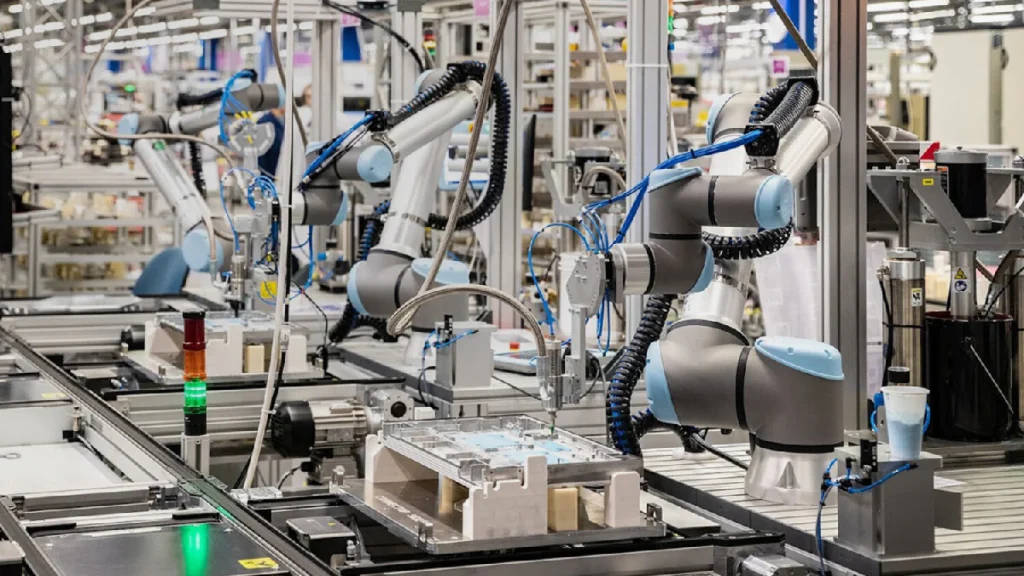

5. Enabling Advanced Automation and Industry 4.0

- Integration with Industry 4.0: Pneumatic sensors play a key role in Industry 4.0 by providing the data needed for smart manufacturing and the Internet of Things (IoT). They enable seamless integration of pneumatic systems with digital technologies.

- Smart Systems and Connectivity: Sensors contribute to the development of smart systems that can communicate, analyze, and make decisions based on real-time data. This enhances the overall intelligence and adaptability of automation systems.

Example: In a smart factory, sensors connected to a central control system allow for real-time monitoring and adjustments, enabling a more responsive and efficient production process.

6. Future Trends in Pneumatic Sensors

- Miniaturization and Integration: Future developments in pneumatic sensors will focus on miniaturization and integration, making them more compact and versatile. This will enable their use in a wider range of applications and environments.

- Enhanced Data Analytics: Advances in data analytics will allow for more sophisticated analysis of sensor data, providing deeper insights and enabling more precise control and optimization of pneumatic systems.

- Wireless and IoT Connectivity: The integration of wireless technologies and IoT will enhance the connectivity of pneumatic sensors, enabling remote monitoring and control, and facilitating more dynamic and flexible automation systems.

Example: Emerging wireless pressure sensors will provide real-time data without the need for complex wiring, simplifying installation and enhancing system flexibility.

7. Best Practices for Implementing Pneumatic Sensors

- Choose the Right Sensor: Select sensors that are compatible with your application and provide the required accuracy and reliability. Consider factors such as range, sensitivity, and environmental conditions.

- Regular Calibration and Maintenance: Ensure that sensors are regularly calibrated and maintained to provide accurate and reliable data. Follow manufacturer recommendations for maintenance procedures.

- Integrate with Control Systems: Integrate sensors with your control systems to maximize their benefits. Ensure that data from sensors is effectively used to inform system adjustments and optimizations.

Example: Regularly calibrate flow sensors in a production line to ensure accurate measurement of air flow and prevent inaccuracies that could affect product quality.

Conclusion

Pneumatic sensors are shaping the future of automation by enhancing precision, improving system efficiency, enabling predictive maintenance, and integrating with advanced technologies. By understanding their role and benefits, and adopting best practices for their implementation, you can leverage pneumatic sensors to optimize your automation systems and stay ahead in the rapidly evolving industrial landscape. At Pneumation.ca, we are committed to providing high-quality pneumatic sensors and expert support to help you achieve superior performance in your automation applications. For more information or assistance with pneumatic sensors, contact us today.