Medical Device Manufacturing Automation

Canada’s biotech and medical industry is a key economic sector, encompassing pharmaceuticals, medical technology, and health IT solutions. Major players such as Sanofi Pasteur, Boston Scientific, Johnson & Johnson, and Baxter lead this innovative field. In this industry, every step matters. With Humphrey Automation’s advanced medical automation solutions and medical device assembly automation systems, we empower breakthroughs that redefine standards and advance healthcare. Our precision-driven technologies support medical innovators in creating future-forward health solutions. It’s more than automation—it’s about enhancing lives.

Humphrey Automation is the official distributor in Canada for medical automation

systems, delivering cutting-edge solutions for the industry.

The right Automation solutions for Medical Device Manufacturing

- Dialysis Systems

- Blood Analyzers

- Dental Systems

- Ventilators & O2 Concentrators

- Robot-Assisted Surgery

- Biotech Research & More

Featured Automation Products for Medical Industry

Koganei

005 Micro Valve Series

Koganei

Fluoropolymer Valve

Humphrey Products

MiDP Stepper operated Inert Diaphragm valves

RTA

Electric Cylinders for Stepping and Servo Motors

Interested in purchasing or learning more about our products?

Further Uses Cases in Medical & Biotech

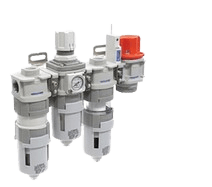

01. Pneumatic Components and Equipment

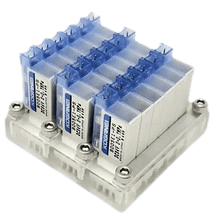

Managing over 150 flow paths efficiently, minimizing the space used, and decreasing the chances of leaks and assembly mistakes.

Koganei’s 005 Series micro solenoid valve manifold met the performance and envelope requirements. Providing the complete sub-assembly ensured accurate and fast installation.

In medical environments, devices like ventilators play a pivotal role in patient care and recovery. The precision and reliability with which these devices control airflow can mean the difference between life and death. Fabco Air’s F Series FRLs (filters, regulators, lubricators) are designed to provide clean, regulated air, guaranteeing both patient safety and the flawless functionality of these indispensable tools.

Furthermore, Humphrey products are at the forefront of innovation when it comes to valves for oxygen concentrators. Recognized for their unparalleled performance and durability, Humphrey valves ensure that respiratory devices deliver oxygen efficiently and consistently. By choosing Humphrey, medical professionals are equipped with top-tier components that stand up to the demands of critical care situations, ensuring both operational excellence and enhanced patient safety.

Bioreactors are extensively used in the biotech industry for cultivating cells for research or pharmaceutical production. Maintaining an optimal environment inside the bioreactor is crucial. Knocks’ FRL units can regulate the air supply, maintaining the right pressure and purity levels for the growth of cells.

Automated laboratory equipment, such as liquid handling systems or sample analyzers, often require precise fluid control. Humphrey Products’ ProControl series, with their high level of precision and reliability, are ideal for such tasks. These proportional solenoid valves can accurately control the flow of reagents, enabling consistent results in laboratory tests.

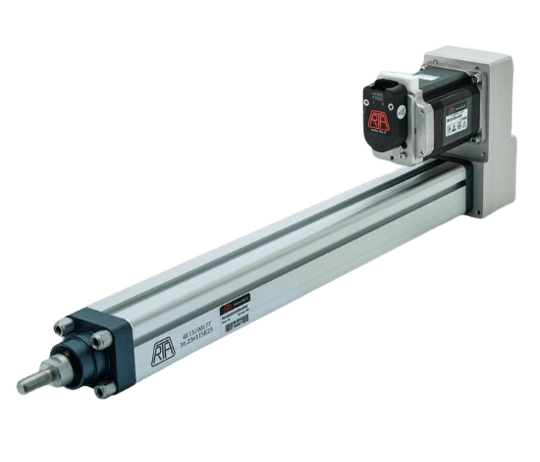

02. Electrical Motion Systems

Robotic surgery is an evolving field requiring the highest level of precision. RTA’s I2 series stepper motors can drive the intricate movements of surgical robots, allowing for minimally invasive procedures and improved patient outcomes.

Infusion pumps, essential in delivering controlled doses of medications to patients, demand utmost precision and reliability. Central to meeting these stringent requirements is the motor technology that drives these devices. RTA’s servo motors are at the forefront, offering unparalleled accuracy and consistency in fluid delivery. Their advanced control capabilities ensure that the exact volume of medication is administered at the precise rate, eliminating the margin for error.

RTA Electric Cylinders deliver precision motion control, integral for dental electric chair adjustments. Boasting high repeatability and accuracy, these cylinders ensure exact positioning, vital for intricate dental procedures. Their robust construction minimizes maintenance downtime, while their efficient design offers consistent performance, even under continuous use. For dental practices seeking reliable, precision-driven solutions, RTA Electric Cylinders represent the gold standard in chair adjustment technology.

03. Machine Vision Systems

Medical stopcocks are integral components in the healthcare sector, facilitating precise control of fluid flow. Their structural and functional integrity directly impacts patient safety and the efficiency of various medical procedures.

Challenge:

Manufacturing medical stopcocks presents a unique set of challenges. Over time and through multiple production cycles, various defects can manifest. These defects, if undetected, can compromise the safety and effectiveness of the stopcock. Notable defects include:

- Sink Marks: Resulting from premature hardening of the external plastic shell before the inner plastic cools.

- Short Shots: Incomplete molding due to an insufficient plastic material quantity.

- Burn Marks: Caused by trapped compressed air during molding, which can weaken the component.

- Flash Marks: Excess plastic ridges that can affect the stopcock’s performance and seal.

Solution with Inspekto Vision System:

To combat these challenges, the Inspekto Vision System is seamlessly integrated into the production process. Harnessing state-of-the-art imaging technology and AI-driven detection algorithms, the system offers:

- Plastic Handle Inspection: Detailed scrutiny ensures each handle is defect-free and conforms to ergonomic and operational standards.

- Shade Variation Detection: Identifies even minor shade changes that might indicate material inconsistencies.

- Mold Change Monitoring: Tracks and reports any deviations over time, signaling when molds might need maintenance or replacement.

- Real-time Defect Detection: The system instantly recognizes and flags any of the aforementioned defects, ensuring only top-quality stopcocks move to the next phase of production.

Background:

Vials and syringes are primary containers for drugs, vaccines, and other biological products. Ensuring their integrity and cleanliness is crucial for patient safety.

Challenge:

Contaminants, cracks, or imperfections in vials and syringes can compromise the sterility and efficacy of the contained product.

Solution with Inspekto Vision System:

The system conducts a thorough inspection of each vial and syringe, detecting any particulate matter inside, ensuring proper cap sealing, and identifying micro-cracks or other imperfections that might be invisible to the naked eye.

Use Case:

When it comes to implantable medical devices like pacemakers, stents, or joint replacements, the margin for error is virtually nonexistent. Here, the Inspekto S70 can be an invaluable tool for manufacturers. Its ability to perform detailed visual inspections can ensure the highest levels of quality control.

For instance, during the manufacturing process of joint replacements, the Inspekto S70 can be used to inspect the surface finish quality, ensuring that there are no irregularities or defects which might lead to complications post-implantation. The system can inspect various features such as coating uniformity, dimensional accuracy, and the smoothness of edges to guarantee the device meets stringent medical standards, thereby preventing faulty devices from advancing to the next stage in the production line.

Use Case:

Medical products often require specialized packaging to maintain sterility and functionality. The Inspekto S70 can be utilized to inspect the integrity of medical packaging, such as blister packs, sealed pouches, and boxed kits. The system can be configured to automatically inspect the seals of these packages, ensuring that they are intact and have not been compromised, which might lead to product contamination.

For example, in the production line of a pharmaceutical company, the Inspekto S70 could be set up to inspect blister packs, checking the uniformity of the aluminum foil seal, and ensuring that each cavity contains a pill. The system can detect defects such as tears, punctures, or improper sealing and can even verify the correct labeling, ensuring that each package is correctly marked with the appropriate batch number and expiry date. This not only guarantees the safety and efficacy of the medical products but also helps in maintaining regulatory compliance and reducing the risk of recalls.

Each of these use cases illustrates how the Inspekto S70, with its advanced visual inspection capabilities, can significantly enhance quality control and assurance processes in the medical device sector, fostering increased safety and reliability.

Want to know more about our custom solutions process?

Automation Solutions for Medical Device Manufacturing

Discover tailored automation solutions for biotech and medical manufacturing. Our advanced automation systems ensure precision, efficiency, and innovation in every step of production.