Pneumatic valves are essential components in automated systems, controlling the flow and direction of compressed air to ensure smooth and efficient operation. At Pneumation.ca, we are excited to introduce our latest range of high-efficiency pneumatic valves, designed to enhance performance, reliability, and energy efficiency in various applications. This article provides an overview of our new product range, highlighting their features, benefits, and applications, and demonstrating how they can improve your pneumatic systems.

1. What Are Pneumatic Valves?

- Definition and Function: Pneumatic valves control the flow, direction, and pressure of compressed air within a pneumatic system. They act as the “switches” that manage the distribution of air to different components, such as actuators and cylinders.

- Types of Pneumatic Valves: Common types include directional control valves, pressure control valves, and flow control valves. Each type serves a specific purpose in regulating the pneumatic system.

Example: A directional control valve might be used to change the direction of airflow in a pneumatic cylinder, allowing it to extend or retract as needed.

2. Features of Our Latest Range of High-Efficiency Pneumatic Valves

- Enhanced Energy Efficiency: Our new range features advanced designs that minimize energy loss and improve overall efficiency. This includes optimized flow paths and reduced pressure drops, leading to lower energy consumption and operating costs.

- Improved Durability: The valves are built with high-quality materials and robust construction to withstand demanding industrial environments. This ensures long-lasting performance and reduces the need for frequent replacements.

- Compact and Lightweight Design: Our valves are designed to be compact and lightweight, making them easy to integrate into tight spaces and reducing the overall weight of your pneumatic system.

- Advanced Control Options: The latest valves come with enhanced control options, including electronic and proportional controls, allowing for precise and adaptable regulation of air flow and pressure.

Example: The new high-efficiency valves feature a streamlined design that reduces turbulence and pressure drop, resulting in more efficient air distribution and lower energy usage.

3. Benefits of High-Efficiency Pneumatic Valves

- Reduced Operating Costs: By improving energy efficiency and reducing pressure drops, our high-efficiency valves help lower the overall operating costs of your pneumatic systems.

- Increased System Reliability: Enhanced durability and robust construction mean fewer breakdowns and maintenance requirements, leading to increased system reliability and uptime.

- Improved Performance: The advanced control options and optimized flow paths contribute to more precise and effective operation, improving the overall performance of your pneumatic systems.

Example: Implementing our high-efficiency valves in a manufacturing line can lead to significant cost savings through reduced energy consumption and improved process control.

4. Applications of High-Efficiency Pneumatic Valves

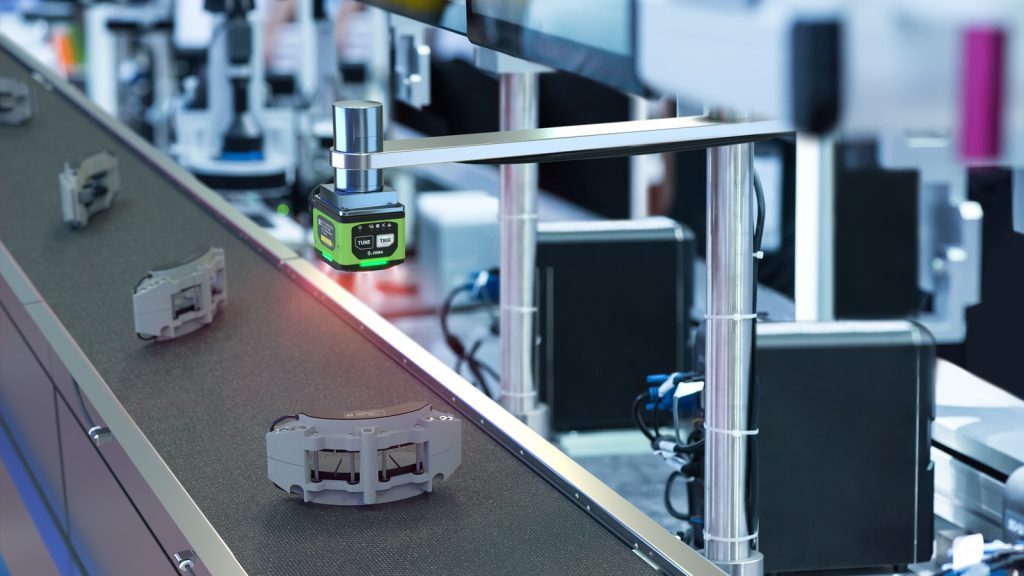

- Manufacturing and Automation: Ideal for use in automated production lines, assembly operations, and process control, where precise control and high reliability are crucial.

- Packaging and Material Handling: Effective in packaging systems and material handling processes, where efficient air control is needed for accurate and reliable operation.

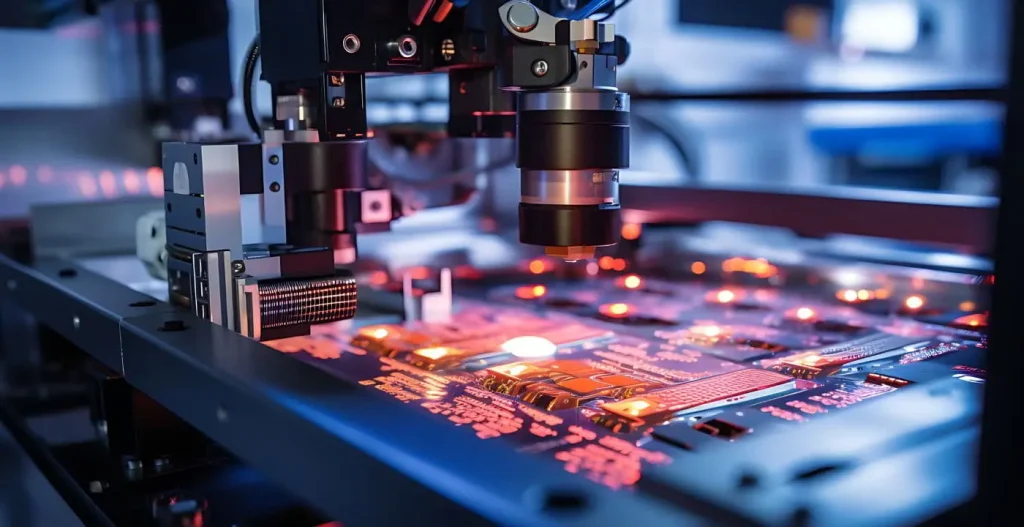

- Automotive and Aerospace: Suitable for applications in automotive and aerospace industries, where high-performance and durability are essential for critical systems.

Example: In an automotive assembly plant, high-efficiency pneumatic valves can enhance the accuracy and speed of robotic arms used for assembly tasks, contributing to overall production efficiency.

5. Installation and Maintenance Tips

- Proper Installation: Ensure that the valves are installed according to the manufacturer’s specifications to avoid issues with leakage or improper operation. Proper alignment and secure connections are essential for optimal performance.

- Regular Maintenance: Perform regular maintenance to check for wear, leaks, and proper functioning. Follow the manufacturer’s guidelines for cleaning, lubrication, and inspection.

- System Integration: Ensure that the new valves are compatible with your existing pneumatic system and control interfaces. Proper integration is crucial for maximizing their benefits and performance.

Example: Regularly inspect and clean the valves to prevent clogging and ensure smooth operation, following the maintenance schedule provided by Pneumation.ca.

6. Why Choose Pneumation.ca’s Pneumatic Valves?

- Quality Assurance: Our valves are manufactured to the highest standards, ensuring reliability, performance, and compliance with industry regulations.

- Expert Support: We provide expert support and guidance to help you select the right valves for your application and assist with installation and maintenance.

- Customer Satisfaction: We are committed to delivering products that meet your needs and exceed your expectations, backed by our excellent customer service and support.

Example: Choose Pneumation.ca for high-quality pneumatic valves and benefit from our extensive expertise and commitment to customer satisfaction.

7. Future Trends in Pneumatic Valve Technology

- Integration with IoT: Future developments may include greater integration with Internet of Things (IoT) technologies, allowing for remote monitoring, diagnostics, and control of pneumatic valves.

- Smart Valves with Advanced Features: Expect to see more smart valves with advanced features such as real-time data analytics, adaptive control, and self-diagnostics.

- Sustainable Designs: There will be a continued focus on designing valves that are environmentally friendly, with reduced energy consumption and recyclable materials.

Example: Future smart pneumatic valves may offer real-time feedback and remote control capabilities, enhancing the adaptability and efficiency of automated systems.

Our latest range of high-efficiency pneumatic valves represents a significant advancement in pneumatic technology, offering enhanced energy efficiency, durability, and performance. By incorporating these valves into your pneumatic systems, you can achieve lower operating costs, increased reliability, and improved overall performance. At Pneumation.ca, we are dedicated to providing top-quality pneumatic components and expert support to meet your needs. For more information about our high-efficiency pneumatic valves or assistance with your pneumatic systems, contact us today.