In the evolving world of automation, pneumatic controllers are crucial for managing and optimizing the operation of pneumatic systems. At Pneumation.ca, we are excited to announce the launch of our new smart pneumatic controllers, designed to bring unprecedented levels of control, efficiency, and intelligence to your automation systems. This article explores the features and benefits of these innovative controllers, what sets them apart, and how they can enhance your pneumatic systems.

1. What Are Pneumatic Controllers?

- Definition and Function: Pneumatic controllers manage and regulate the operation of pneumatic systems, including valves, cylinders, and other components. They control parameters such as pressure, flow, and direction to ensure the system operates efficiently and accurately.

- Types of Controllers: Pneumatic controllers can be manual or automated. Smart pneumatic controllers incorporate advanced features like sensors, connectivity, and programmable logic to provide enhanced control and automation.

Example: In an automated production line, a pneumatic controller might adjust the pressure and flow of compressed air to control the movement of cylinders and actuators, ensuring precise operation.

2. Key Features of Our New Smart Pneumatic Controllers

- Advanced Connectivity: Our smart controllers feature advanced connectivity options, including IoT and network integration, allowing for real-time monitoring and control from anywhere. This enables remote management and data collection for better system oversight.

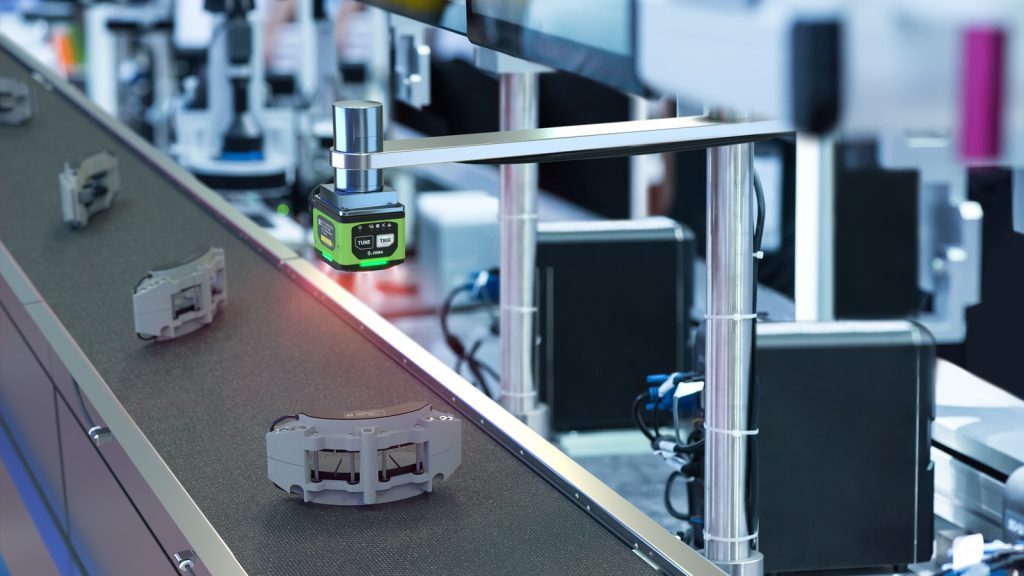

- Real-Time Data Analytics: Equipped with sensors and data analytics capabilities, the controllers provide real-time feedback on system performance, helping to identify issues and optimize operation. This includes monitoring parameters such as pressure, temperature, and flow rates.

- Programmable Logic: The new controllers offer programmable logic features, allowing for customizable control sequences and automation routines. This flexibility enables tailored solutions for complex applications.

- User-Friendly Interface: Designed with a user-friendly interface, our smart controllers make it easy to configure and adjust settings. The intuitive design simplifies setup and operation, reducing the learning curve and improving efficiency.

- Enhanced Security: With built-in security features, including encryption and access control, our smart controllers ensure safe and secure operation, protecting your system from unauthorized access and potential breaches.

Example: The advanced connectivity of our smart controllers allows for remote adjustments and monitoring of pneumatic systems, enhancing flexibility and responsiveness in dynamic environments.

3. Benefits of Smart Pneumatic Controllers

- Improved Efficiency: By providing real-time data and analytics, our smart controllers help optimize system performance and energy usage, leading to reduced operational costs and increased efficiency.

- Increased Flexibility: The programmable logic and customizable features allow for adaptable control sequences and automation routines, making it easier to meet specific application needs and respond to changing requirements.

- Enhanced Monitoring and Diagnostics: Real-time feedback and data analytics enable proactive maintenance and quick issue resolution, reducing downtime and improving overall system reliability.

- Remote Management: The connectivity features allow for remote monitoring and control, providing greater flexibility and convenience in managing pneumatic systems.

Example: Utilizing our smart controllers in a manufacturing facility can lead to significant improvements in process efficiency and reliability, thanks to their advanced monitoring and remote management capabilities.

4. Applications of Smart Pneumatic Controllers

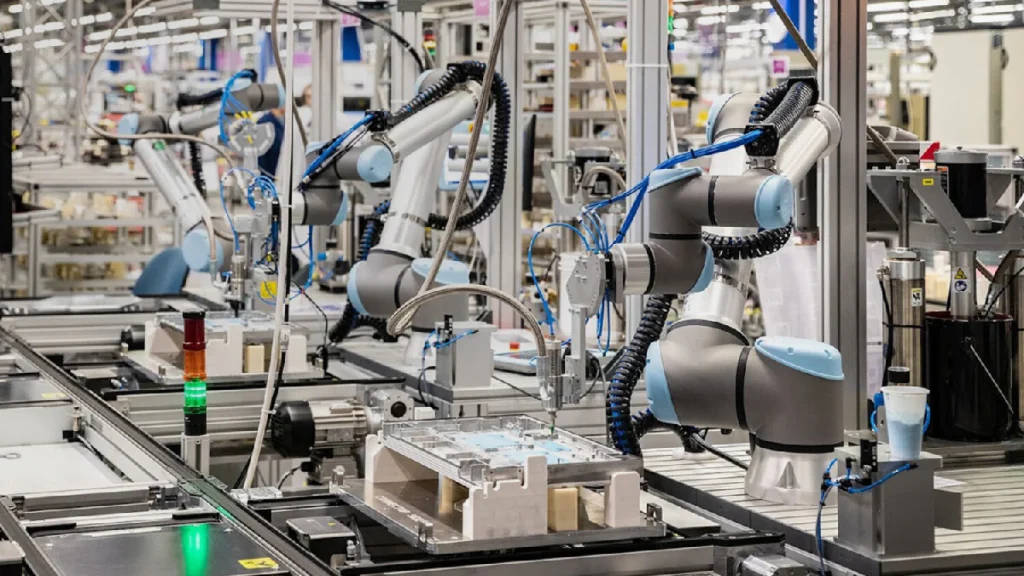

- Manufacturing and Automation: Ideal for complex manufacturing and automation systems where precise control and real-time monitoring are required for tasks such as assembly, material handling, and packaging.

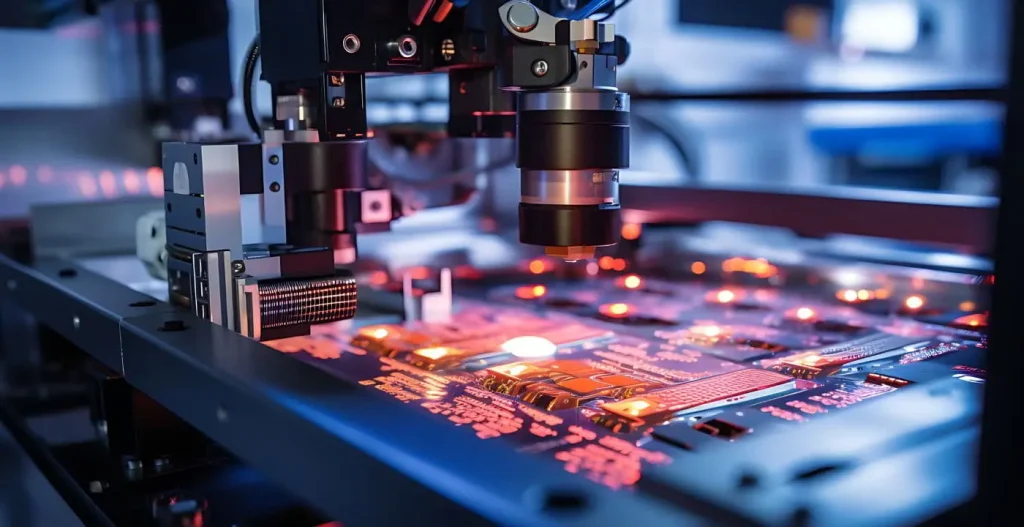

- Process Control: Effective in process control applications where accurate regulation of pneumatic parameters is essential for maintaining product quality and system performance.

- Robotic Systems: Suitable for integration into robotic systems, providing intelligent control and automation for tasks such as positioning, gripping, and assembly.

Example: In a process control application, our smart pneumatic controllers can regulate the pressure and flow of air to maintain consistent quality in the production of sensitive components.

5. How to Integrate Smart Pneumatic Controllers into Your System

- Assess System Requirements: Evaluate your system’s needs, including connectivity, data monitoring, and control features. Determine the specific requirements for integration, such as communication protocols and compatibility with existing components.

- Select the Right Model: Choose a smart pneumatic controller model that matches your application needs and provides the necessary features and functionality.

- Consult with Experts: For complex integrations, consult with our experts at Pneumation.ca to ensure a seamless and effective implementation of the smart controllers in your system.

Example: Our team can assist in selecting the appropriate smart controller model and configuring it for optimal performance in your automation system, ensuring compatibility and effective integration.

6. Installation and Maintenance Tips

- Follow Installation Guidelines: Adhere to the manufacturer’s guidelines for installation, including proper wiring, connectivity, and mounting. Ensure the controller is integrated correctly with your pneumatic system.

- Regular Maintenance: Perform regular maintenance checks to ensure the controller is operating correctly and address any issues promptly. This includes software updates and system diagnostics.

- Utilize Data Analytics: Leverage the data analytics capabilities of the smart controller to monitor system performance and identify areas for improvement.

Example: Regularly review performance data provided by the smart controller to optimize system settings and address any potential issues before they impact operation.

7. Future Trends in Pneumatic Controller Technology

- Increased Integration with AI: Future developments may include greater integration with artificial intelligence (AI) for adaptive control and predictive maintenance based on data analysis.

- Enhanced Connectivity Options: Expect to see more advanced connectivity options, including integration with emerging technologies and communication standards.

- Greater Customization: There will be a focus on providing more customizable solutions, allowing for tailored control and automation features to meet specific application needs.

Example: Future smart pneumatic controllers may incorporate AI algorithms to automatically adjust control parameters based on real-time data, enhancing adaptability and efficiency.

Our new smart pneumatic controllers represent a significant advancement in pneumatic technology, offering enhanced connectivity, real-time data analytics, and programmable logic for improved control and efficiency. By incorporating these controllers into your pneumatic systems, you can achieve greater flexibility, reliability, and performance. At Pneumation.ca, we are dedicated to providing innovative solutions and expert support to meet your automation needs. For more information about our smart pneumatic controllers or assistance with your systems, contact us today.