In today’s industrial landscape, data-driven decision-making has become a cornerstone of operational excellence. For pneumatic systems, leveraging data can significantly enhance automation performance, improve efficiency, and reduce operational costs. At Pneumation.ca, we understand the importance of integrating data into your pneumatic systems to optimize performance. This article explores how data can be utilized to improve automation in pneumatic systems, offering practical insights and strategies for achieving better results.

1. Implement Real-Time Monitoring

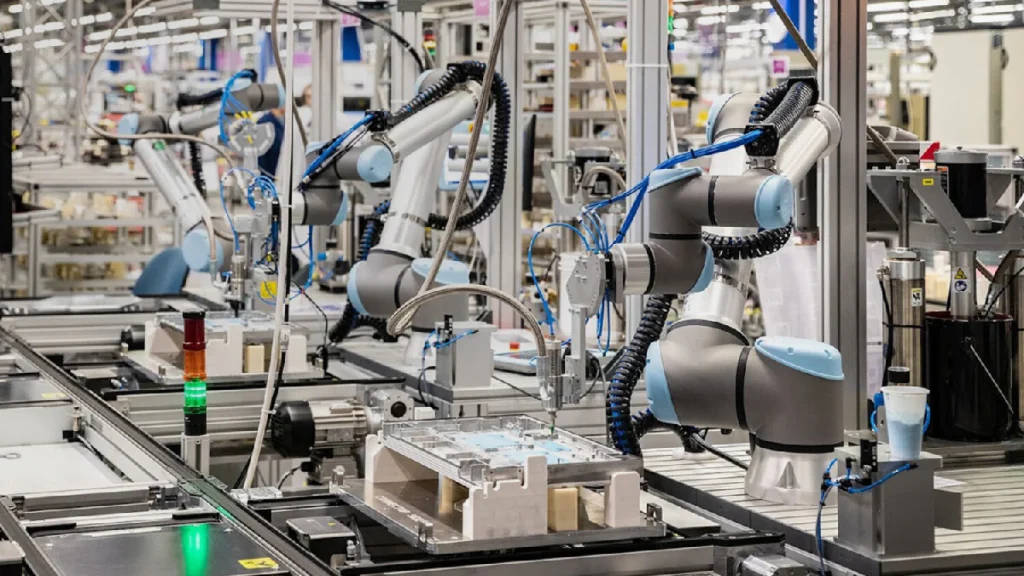

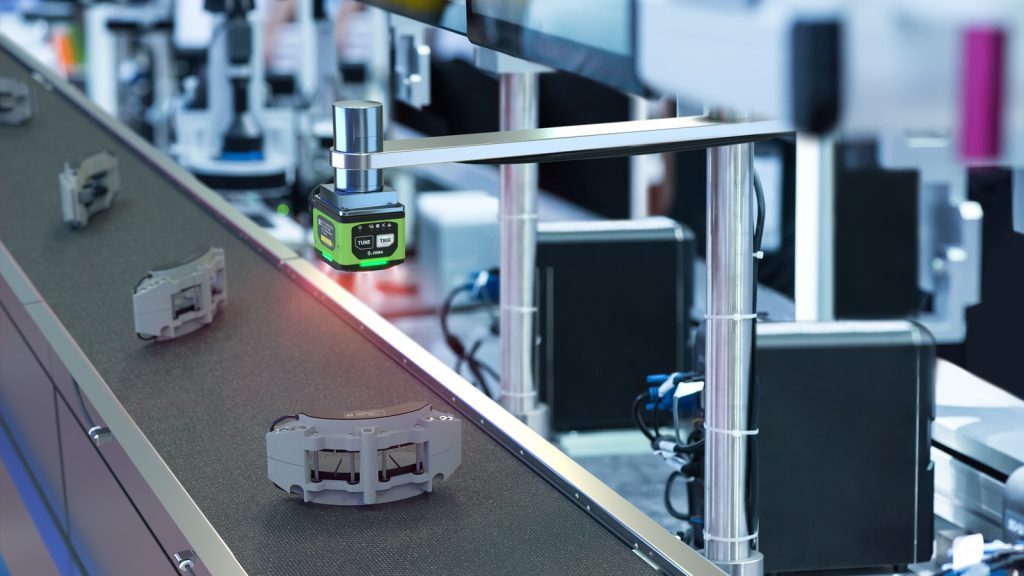

- Install Sensors and Data Acquisition Tools: Equip your pneumatic system with sensors to monitor key parameters such as pressure, temperature, flow rate, and actuator position. Data acquisition tools collect this information in real time, providing valuable insights into system performance.

- Utilize Data Visualization: Use data visualization tools to interpret and analyze the collected data. Dashboards and graphical representations help operators quickly understand system status and identify potential issues.

Example: By installing pressure sensors and flow meters, you can continuously monitor air pressure and flow rates, allowing for immediate adjustments to optimize system performance and prevent issues before they escalate.

2. Analyze Performance Data for Optimization

- Perform Data Analysis: Analyze historical and real-time data to identify trends and patterns in system performance. Look for anomalies, inefficiencies, or recurring issues that could indicate areas for improvement.

- Optimize System Parameters: Use the insights gained from data analysis to adjust system parameters, such as pressure settings, flow rates, and actuator speeds. This helps in fine-tuning the system for optimal performance and efficiency.

Example: Data analysis might reveal that certain components are frequently operating outside their optimal range. Adjusting pressure settings or upgrading components based on this data can enhance overall system efficiency.

3. Predictive Maintenance through Data

- Implement Predictive Analytics: Utilize predictive analytics to forecast potential equipment failures before they occur. Analyze data trends to predict when components might need maintenance or replacement, allowing for proactive action.

- Schedule Maintenance Based on Data: Use data-driven insights to schedule maintenance activities more effectively. Predictive maintenance can reduce unplanned downtime and extend the life of pneumatic components.

Example: By analyzing vibration data from actuators, you can predict when bearings might need lubrication or replacement, thus avoiding unexpected breakdowns and minimizing downtime.

4. Enhance System Efficiency with Data-Driven Controls

- Automate Controls Based on Data: Integrate automated control systems, such as PLCs or advanced control algorithms, that adjust system operations based on real-time data. This allows for dynamic adjustments to maintain optimal performance.

- Use Data for Adaptive Control: Implement adaptive control strategies that adjust system settings based on changing conditions or data inputs. This ensures that the system operates efficiently even as parameters or demands fluctuate.

Example: A PLC could adjust actuator speeds and valve positions in real-time based on data from sensors, optimizing energy use and improving process accuracy.

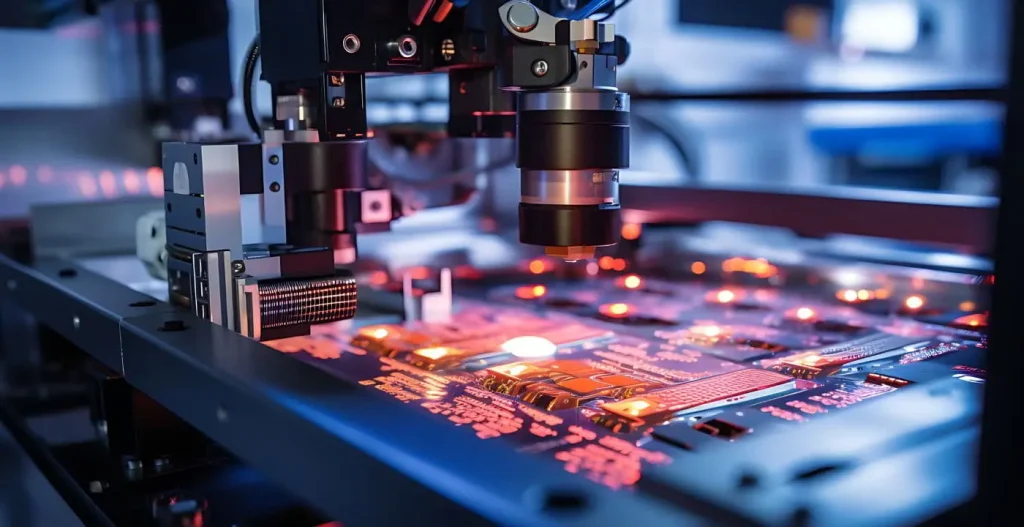

5. Improve Quality and Consistency

- Monitor and Control Quality Metrics: Use data to monitor quality metrics and ensure consistent product output. Track variables that impact product quality and make data-driven adjustments to maintain standards.

- Reduce Variability: Analyze data to identify sources of variability in the automation process. Implement controls and adjustments to reduce variability and improve overall consistency in production.

Example: Data on product dimensions and output rates can be used to adjust process parameters, ensuring that products meet quality standards consistently.

6. Enhance Troubleshooting with Data

- Use Data for Root Cause Analysis: Leverage data to diagnose and troubleshoot issues more effectively. Analyzing performance data helps identify the root cause of problems, leading to more targeted and effective solutions.

- Create Diagnostic Reports: Generate diagnostic reports based on collected data to assist in troubleshooting. Detailed reports provide insights into system performance and potential issues.

Example: Data logs from sensors can pinpoint the exact time and conditions under which a problem occurred, aiding in quicker and more accurate troubleshooting.

7. Foster Continuous Improvement

- Implement Continuous Improvement Practices: Use data to drive continuous improvement initiatives. Regularly review performance data to identify opportunities for enhancement and implement changes accordingly.

- Encourage Data-Driven Culture: Promote a culture of data-driven decision-making within your organization. Encourage team members to utilize data for performance optimization and problem-solving.

Example: Establish regular review meetings where performance data is analyzed to identify areas for improvement and discuss strategies for optimization based on the data.

Conclusion

Leveraging data in pneumatic systems can lead to significant improvements in automation performance, efficiency, and reliability. By implementing real-time monitoring, analyzing performance data, utilizing predictive maintenance, enhancing system controls, improving quality and consistency, and fostering a data-driven culture, you can optimize your pneumatic automation systems and achieve better results. At Pneumation.ca, we are committed to helping you harness the power of data to enhance your pneumatic systems. For more information or assistance with your data-driven initiatives, contact us today.