Safety is paramount in industrial automation, and as pneumatic systems have evolved, so too have the safety standards that govern their use. The evolution of safety standards in pneumatic automation reflects the growing complexity of these systems and the need to protect both workers and equipment. At Pneumation.ca, we are committed to providing pneumatic solutions that not only enhance productivity but also adhere to the highest safety standards. Understanding the history and future direction of these standards is crucial for businesses looking to ensure safe and efficient operations.

The Importance of Safety in Pneumatic Automation

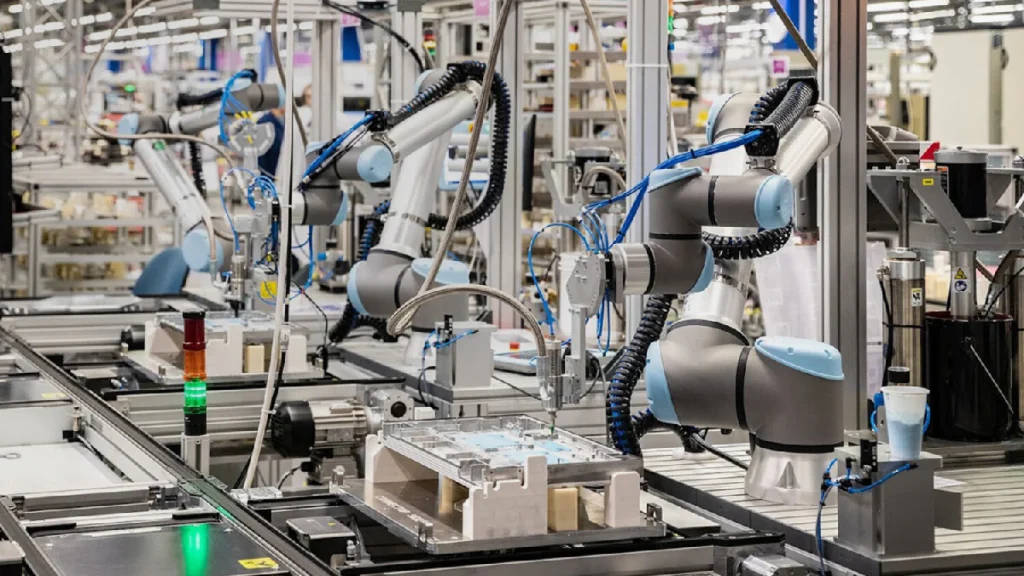

Pneumatic systems are widely used in industrial settings due to their reliability, efficiency, and cost-effectiveness. However, they also present risks, including potential hazards related to high pressure, mechanical movement, and energy storage. Ensuring that these systems operate safely is essential to prevent accidents, injuries, and costly downtime. Over the years, safety standards have been developed and refined to address these risks, providing guidelines for the design, installation, operation, and maintenance of pneumatic systems.

Historical Overview of Pneumatic Safety Standards

- Early Safety Practices

- In the early days of pneumatic automation, safety practices were primarily based on experience and common sense. Operators relied on mechanical safeguards, such as guards and barriers, to prevent accidental contact with moving parts. However, as pneumatic systems became more complex, the limitations of these basic safety measures became apparent, leading to the development of more formalized safety standards.

- Introduction of Regulatory Standards

- The introduction of regulatory standards in the mid-20th century marked a significant shift in pneumatic safety. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States and the International Organization for Standardization (ISO) began to develop guidelines specifically for pneumatic systems. These early standards focused on basic safety measures, such as proper installation, regular maintenance, and the use of emergency stop mechanisms.

- The Rise of Functional Safety

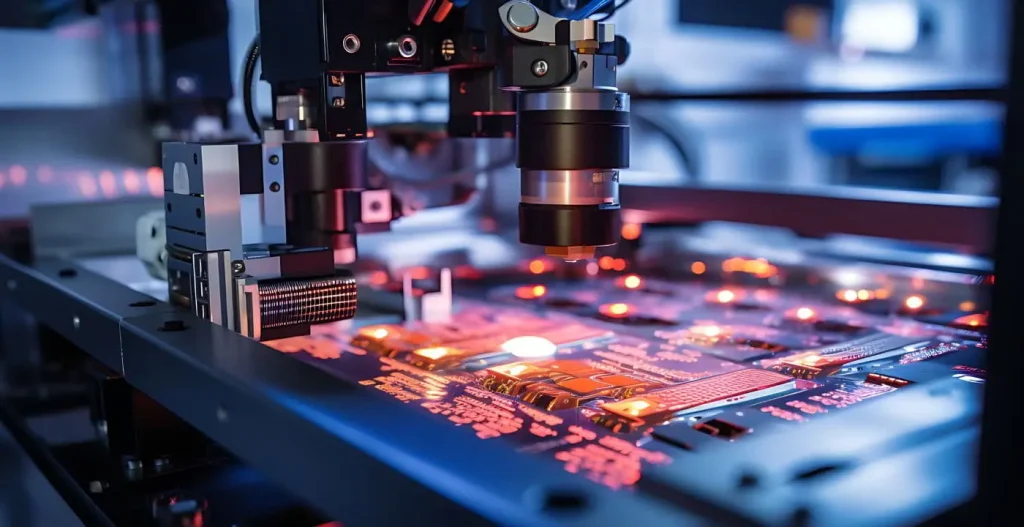

- As pneumatic automation continued to advance, the concept of functional safety emerged. Functional safety refers to the safety measures that ensure a system operates correctly in response to its inputs, even in the event of a fault. Standards such as ISO 13849 and IEC 61508 introduced requirements for the design and implementation of safety-related control systems, including those used in pneumatics. These standards emphasized risk assessment, redundancy, and the use of fail-safe mechanisms.

Modern Safety Standards in Pneumatic Automation

- Comprehensive Risk Assessment

- Modern safety standards place a strong emphasis on comprehensive risk assessment. Before a pneumatic system is designed or installed, a thorough analysis of potential hazards must be conducted. This includes identifying all possible sources of risk, evaluating their likelihood and severity, and implementing measures to mitigate them. At Pneumation.ca, we provide expert guidance on conducting risk assessments, helping businesses ensure that their pneumatic systems meet the latest safety standards.

- Integration of Safety Technology

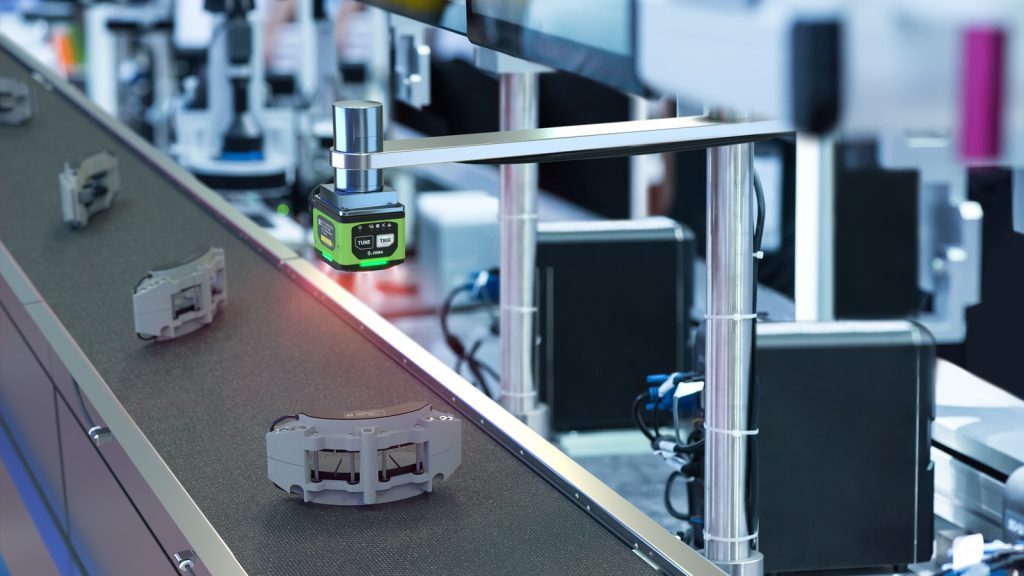

- The integration of advanced safety technology is a key trend in modern pneumatic systems. Safety devices such as pressure relief valves, safety interlocks, and emergency shut-off systems are now standard in many pneumatic applications. Additionally, the use of safety PLCs (Programmable Logic Controllers) and safety sensors allows for real-time monitoring and control of safety functions, ensuring that the system responds immediately to any detected hazard.

- Compliance with International Standards

- Compliance with international safety standards is essential for businesses operating in a global market. Standards such as ISO 4414 (Pneumatic fluid power – General rules and safety requirements for systems and their components) and ISO 13849 (Safety of machinery – Safety-related parts of control systems) provide comprehensive guidelines for ensuring the safety of pneumatic systems. These standards cover everything from system design and component selection to installation, operation, and maintenance. At Pneumation.ca, we offer pneumatic solutions that fully comply with these international standards, giving our customers peace of mind.

- Training and Safety Culture

- Another important aspect of modern safety standards is the emphasis on training and fostering a safety culture within the workplace. Ensuring that operators and maintenance personnel are properly trained in the safe use of pneumatic systems is crucial. This includes understanding the safety features of the system, recognizing potential hazards, and knowing how to respond in an emergency. At Pneumation.ca, we provide training and resources to help businesses cultivate a strong safety culture.

The Future of Safety Standards in Pneumatic Automation

As pneumatic systems continue to evolve, so too will the safety standards that govern them. The future of pneumatic safety will likely see greater integration of smart technology, enabling even more precise monitoring and control of safety functions. Additionally, as automation becomes more widespread, the need for standardized safety protocols will grow, driving the development of new standards that address emerging risks. At Pneumation.ca, we are committed to staying ahead of these trends, offering solutions that not only meet current safety standards but are also designed for the future.

The evolution of safety standards in pneumatic automation reflects the increasing complexity and sophistication of these systems. From early mechanical safeguards to modern functional safety standards, the focus has always been on protecting workers and ensuring the reliable operation of pneumatic systems. At Pneumation.ca, we are dedicated to providing pneumatic solutions that adhere to the highest safety standards, helping our customers achieve safe and efficient operations in today’s dynamic industrial environment.