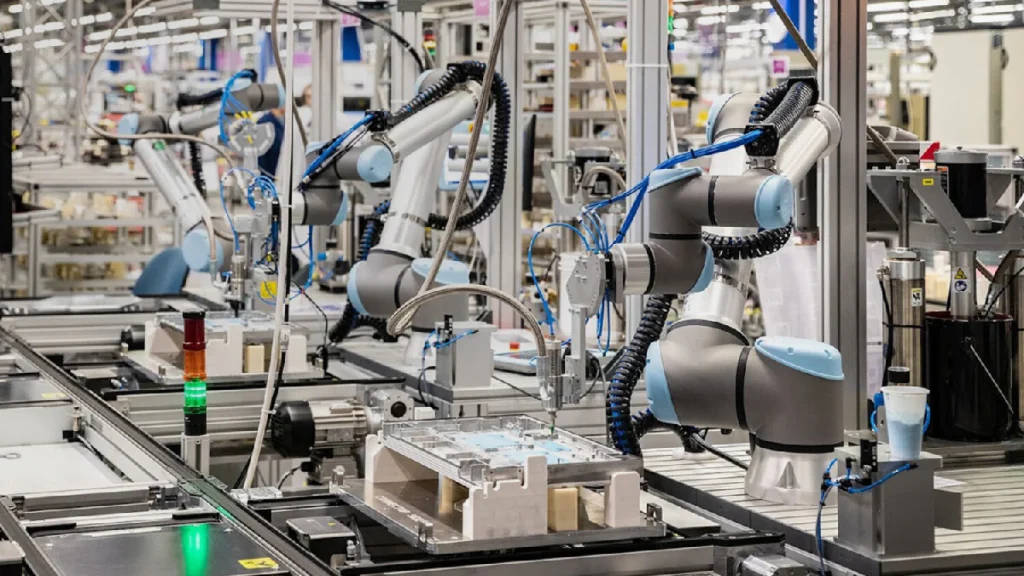

The advent of Industry 4.0, characterized by the integration of digital technologies such as IoT, artificial intelligence, and big data into manufacturing processes, is revolutionizing industries across the globe. Pneumatic systems, which have long been a staple in industrial automation, are undergoing significant transformation due to these advancements. At Pneumation.ca, we are committed to helping businesses navigate this new landscape by offering innovative pneumatic solutions that leverage the power of Industry 4.0.

Industry 4.0, often referred to as the Fourth Industrial Revolution, marks a new era in manufacturing where cyber-physical systems, IoT, cloud computing, and cognitive computing are interconnected to create intelligent factories. In these smart factories, machines and systems communicate and cooperate with each other and humans in real-time, leading to more efficient, flexible, and sustainable production processes. Pneumatic systems, being an integral part of industrial automation, are also evolving to meet the demands of this new era.

Key Impacts of Industry 4.0 on Pneumatic Systems

- Enhanced Connectivity and Integration

- One of the most significant impacts of Industry 4.0 on pneumatic systems is the increased connectivity and integration. Pneumatic components such as valves, actuators, and sensors are now equipped with IoT capabilities, allowing them to communicate with other devices and systems in real-time. This connectivity enables more seamless integration of pneumatic systems with other automated processes, leading to more efficient and synchronized operations.

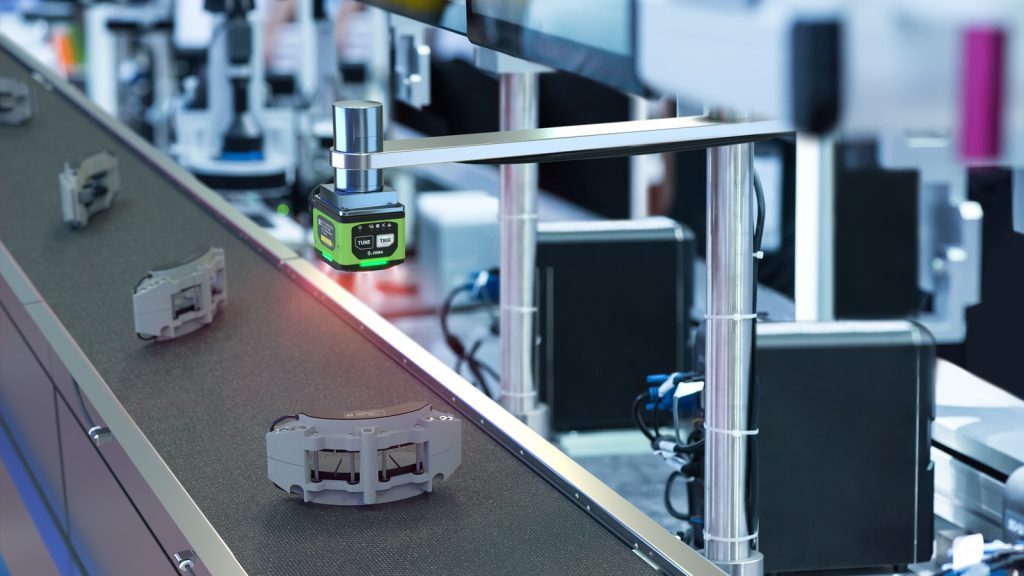

- Real-Time Monitoring and Predictive Maintenance

- Industry 4.0 brings real-time monitoring and predictive maintenance to pneumatic systems. Sensors embedded in pneumatic components collect data on pressure, temperature, flow, and other critical parameters. This data is then analyzed using advanced algorithms to predict potential failures before they occur, enabling proactive maintenance. At Pneumation.ca, we offer smart pneumatic solutions that provide real-time insights, helping businesses reduce downtime and extend the lifespan of their equipment.

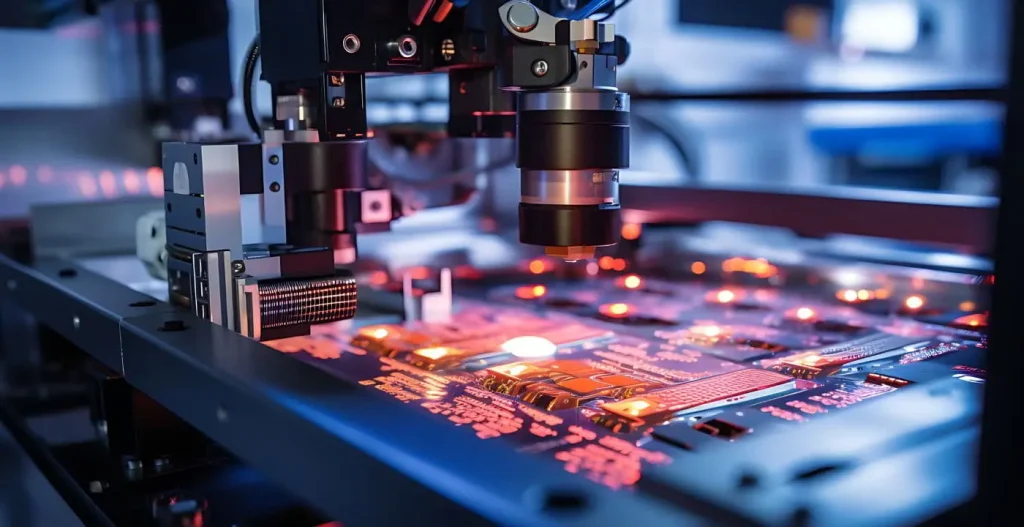

- Increased Efficiency and Energy Savings

- The integration of Industry 4.0 technologies in pneumatic systems leads to significant improvements in efficiency and energy savings. Smart pneumatic systems can adjust their operation based on real-time data, optimizing air pressure, flow rates, and other variables to minimize energy consumption. Additionally, these systems can recover and reuse energy, further reducing operational costs. The result is a more sustainable and cost-effective operation, which is a key benefit of Industry 4.0.

- Greater Flexibility and Customization

- Industry 4.0 enables greater flexibility and customization in pneumatic systems. With the ability to remotely monitor and control pneumatic components, manufacturers can quickly adapt to changing production needs. For instance, smart pneumatic systems can be reprogrammed on the fly to handle different tasks, reducing the need for manual adjustments and downtime. This flexibility is crucial in today’s fast-paced manufacturing environment, where agility and responsiveness are key to staying competitive.

- Data-Driven Decision Making

- The data generated by Industry 4.0-enabled pneumatic systems provides valuable insights that can drive better decision-making. By analyzing trends and patterns in system performance, businesses can identify areas for improvement, optimize processes, and reduce waste. At Pneumation.ca, we help our clients harness the power of data to make informed decisions that enhance their operations and deliver better outcomes.

Challenges and Considerations

While the benefits of Industry 4.0 for pneumatic systems are clear, there are also challenges to consider. Implementing these advanced technologies requires significant investment in infrastructure and training. Additionally, the integration of IT and OT (Operational Technology) systems can be complex and may require careful planning and execution. However, with the right partner, these challenges can be effectively managed. At Pneumation.ca, we provide comprehensive support to help businesses successfully implement Industry 4.0 solutions in their pneumatic systems.

Industry 4.0 is transforming the way pneumatic systems are designed, operated, and maintained. The enhanced connectivity, real-time monitoring, increased efficiency, and data-driven decision-making capabilities brought by this revolution are enabling businesses to achieve new levels of productivity and sustainability. At Pneumation.ca, we are dedicated to providing cutting-edge pneumatic solutions that help our customers thrive in this new era of industrial automation.