What Are Proportional Valves? A Guide to Their Role in Modern Pneumatic Systems

In the age of Industry 4.0 and AI-powered automation, manufacturers are prioritizing smarter, more precise control over their equipment. Traditional pneumatic systems—long valued for their simplicity and reliability—are evolving to meet these new demands. A key component of that evolution? The proportional valve.

This article breaks down what proportional valves are, how they work, and why they’re essential to modern pneumatic systems used in industrial automation, robotics, and machine control.

What Is a Proportional Valve in Pneumatics?

A pneumatic proportional valve is a device that regulates air pressure or flow in a controlled, variable manner based on an electrical signal. Unlike standard on/off solenoid valves, proportional valves offer a full range of control between fully closed and fully open positions.

This means engineers can precisely adjust actuator speed, force, or pressure, enabling better performance and energy efficiency across industrial applications.

How Do Proportional Valves Work?

Proportional valves receive analog or digital input signals (commonly 0–10V or 4–20mA) from a controller or PLC. The valve then adjusts the size of the opening to allow just the right amount of compressed air through. In some systems, this process is closed-loop—using sensors and feedback to ensure exact pressure or flow levels are maintained in real time.

With today’s AI-enhanced systems and edge computing in industrial environments, proportional valve control can be integrated with smart algorithms that continuously optimize performance, reduce energy waste, and predict maintenance needs.

Benefits of Using Proportional Valves in Automation

Modern factories are leveraging proportional valves to improve system performance, flexibility, and energy savings. Here’s why:

1. Precise Pressure and Flow Control

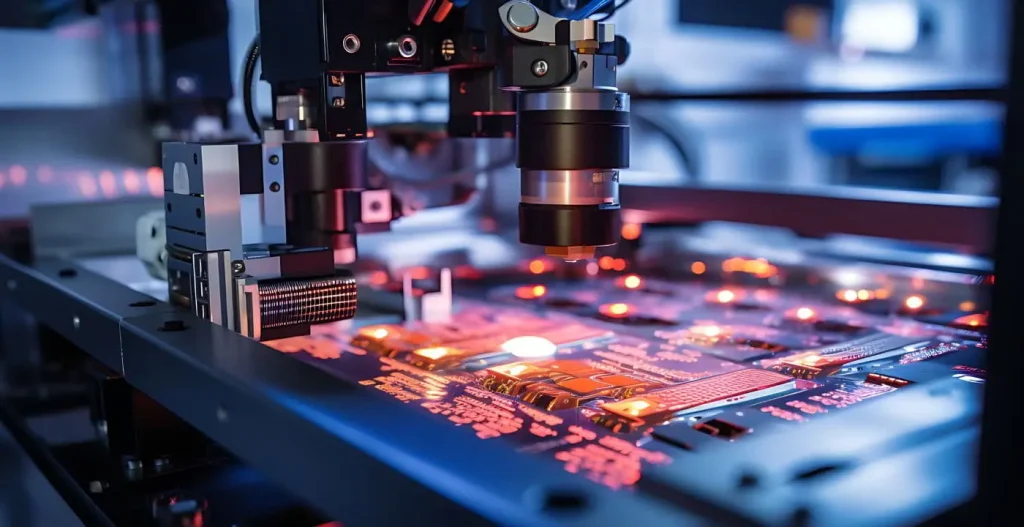

Proportional valves are ideal for applications where exact pressure or flow is required—common in robotics, medical devices, packaging lines, and process control.

2. Improved Machine Performance

When used in motion control systems, these valves enable smooth acceleration and deceleration of pneumatic actuators—reducing wear and increasing accuracy.

3. Energy Efficiency and Cost Savings

By only supplying the air that’s needed, proportional valves help reduce compressed air consumption, resulting in lower operational costs.

4. Smart System Integration

Modern valves can connect to IoT-enabled controllers or AI-powered monitoring systems, enabling predictive maintenance and real-time system optimization.

Typical Applications for Pneumatic Proportional Valves

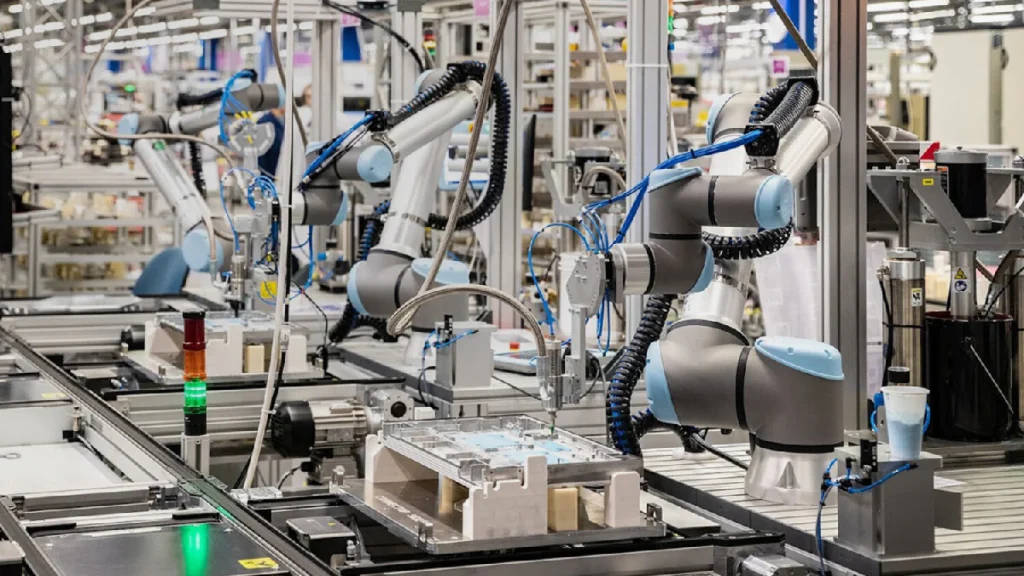

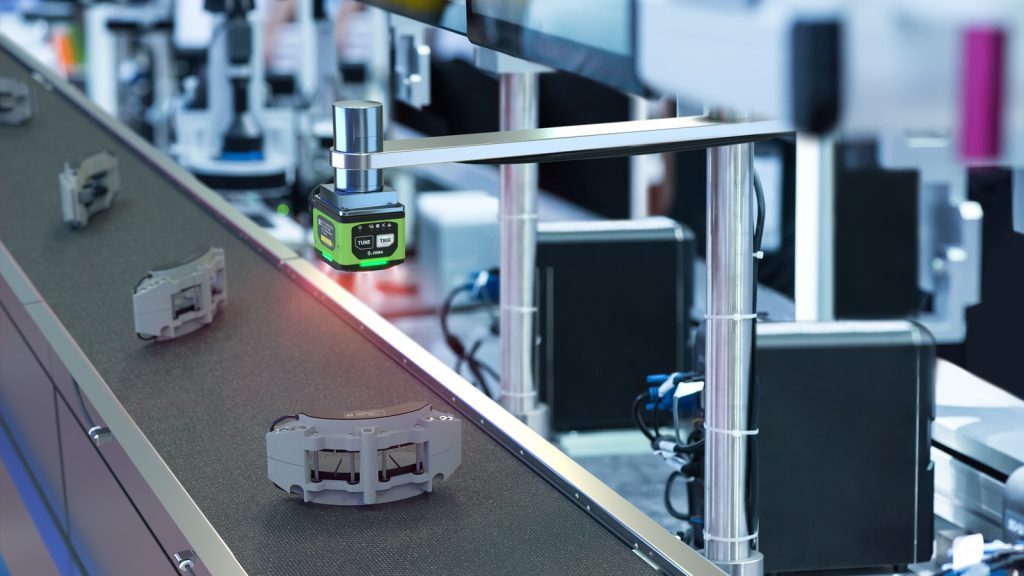

- Automated assembly lines

- Medical and diagnostic equipment

- Material handling systems

- Robotic arms and end-of-arm tooling

- Leak detection and pressure testing systems

These applications all benefit from high-precision airflow control, repeatability, and real-time responsiveness.

Choosing the Right Proportional Valve

When sourcing a proportional valve for your automation system, consider:

- Required flow rate and pressure range

- Type of control signal (voltage, current, or digital)

- Need for integrated sensors or feedback loops

- Mounting and space limitations

- Compatibility with PLCs or industrial Ethernet networks

At Humphrey Automation, we specialize in helping Canadian manufacturers implement the latest pneumatic control technology. Our team will guide you in selecting the best smart proportional valve to match your system requirements and performance goals.

Need Help with Proportional Valves?

Humphrey Automation is your trusted partner for advanced pneumatic systems in Canada. We offer:

✅ Expert guidance on selecting proportional valves

✅ Access to top brands and cutting-edge technology

✅ Full technical support and system integration services

📞 Contact us today to speak with a pneumatic automation expert or request a quote.