Water Technology

Canada’s water technology sector, largely driven by the demand for clean water and efficient wastewater management, is a robust market. Boasting a rich landscape of freshwater, Canada stands at the forefront of water tech advancements. From generating thousands of jobs to attracting international investments and partnerships. This booming sector significantly bolsters the economy, integrating state-of-the-art pneumatic and electrical motion equipment for efficient water management. A beacon of sustainability, Canada is shaping the future of global water solutions.

The right solutions for your water technology system

- Water Purification

- Desalination

- Marine Technology

- Wastewater treatment

- Smart Irrigation Systems

- Automated Water Testing

Featured Products for Water Tech

Habonim

High Pressure Floating Ball 3 Piece valve 28 – up to 255 bar (3700 psi)

Habonim

3 Piece Floating Ball Valve 27

Koganei

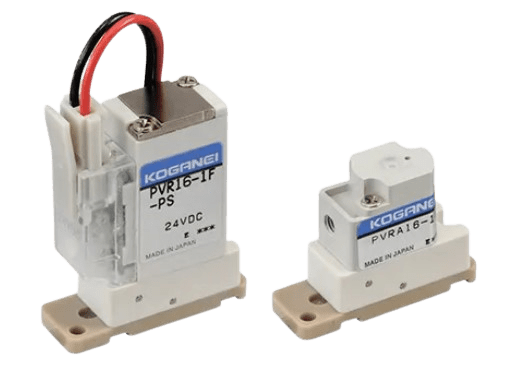

PEEK PVR16 Series Media Isolation Valves

Humphrey Products

310 & 410 Direct Acting Solenoid Valves

Interested in purchasing or learning more about our products?

Further Uses Cases in Water Technology Applications

01. Pneumatic Components and Equipment

Precise control of chemical dosing is critical to maintaining the quality of treated water and preventing overdosing that can lead to adverse reactions. Employing Habonim’s Compact Actuators for regulating chemical flow ensures precise dosage and minimizes risks of overdosing. Coupling this with Humphrey Products’ ProControl Proportional Solenoid Valves, which offer reliable and fine control, creates a system that is more responsive to fluctuations in chemical requirements, ensuring optimal treatment conditions and maintaining water purity standards. The blend of these products ensures minimized chemical waste and optimal treatment conditions, even in the presence of harsh chemicals.

Efficient removal of contaminants from effluents is crucial to prevent environmental pollution and ensure compliance with regulatory standards. Implementing Koganei’s F Series Filters in effluent treatment systems removes impurities and safeguards water quality efficiently. The integration of Humphrey Products’ solenoid valves further refines the system by controlling the flow of treated water meticulously, aiding in effective waste management and compliance with environmental standards. The combination of these products guarantees enhanced system reliability and water quality.

Handling and managing sludge discharge effectively is essential to prevent leakages and environmental contamination. Habonim’s ball valves are pivotal in sludge dewatering processes, ensuring a secure and efficient management of sludge discharge, thus preventing any leakages and maintaining the integrity of the systems. Their durable and robust design can withstand harsh conditions encountered during sludge dewatering, ensuring long-lasting performance and minimal maintenance.

The sustainable and safe reuse of water is critical for conservation and reducing environmental impacts. Habonim’s high-pressure valves are crucial in water recycling systems, allowing for the handling of water under extreme pressures securely and efficiently, mitigating system failures and leakages. The incorporation of these valves is a leap towards sustainability, ensuring the safe reuse of water while minimizing environmental impacts.

Habonim is renowned for its high-quality valve and actuator products. Desalination plants, which convert saltwater into freshwater, present numerous challenges such as corrosion due to the high salt content, high pressures in the reverse osmosis process, and the need for accurate flow control to ensure efficient operations.

For these reasons, the desalination process would benefit greatly from the following Habonim products:

Corrosion-resistant Ball Valves: Given that desalination plants deal with saltwater, there’s a need for valves that can withstand the corrosive nature of salt. Habonim’s stainless steel and special alloy valves can be used in critical areas where corrosion resistance is paramount.

High-pressure Valves: Reverse osmosis, a popular method for desalination, operates under high pressures to force saltwater through membranes. Habonim’s high-pressure valves would be ideal for managing and maintaining these pressures, ensuring that water is pushed through the membranes at the optimal rate.

Compact Actuators: Efficient space utilization is crucial in desalination plants, and Habonim’s compact actuators would ensure that valve operations are automated without taking up excessive space. This would be particularly beneficial in plants where space is at a premium.

Emergency Shutdown Valves: Safety is paramount in desalination plants, and in case of any anomalies or malfunctions, it’s crucial to have a reliable shutdown system. Habonim’s emergency shutdown valves can be integrated into the plant’s safety system to ensure immediate action in case of any issues, preventing potential damages or accidents.

Trunnion Mounted Ball Valves: These are designed for larger pipe sizes and higher pressure operations, which are common in desalination plants. Their design ensures minimal wear and tear, leading to increased lifespan and reduced maintenance needs.

02. Electrical Motion Systems

Challenge: Waste sludge treatment is a critical process in wastewater management. Ineffective or inconsistent manual stirring might not adequately mix the sludge, affecting the treatment efficacy.

Solution: By integrating RTA’s powerful “NEMA 23” stepper motors into the agitation systems, facilities can ensure a consistent and thorough mixing process. This is crucial for breaking down waste components effectively and ensuring that the subsequent treatment processes are efficient.

Challenge: UV disinfection is a non-chemical process used to eliminate pathogens. For this to work, UV lamps need to be consistently positioned to ensure they radiate effectively.

Solution: RTA’s “NEMA 34” series stepper motors, with their precise positional control, can ensure UV lamps remain in optimal positions. This ensures maximum pathogen elimination, safeguarding the water quality.

Challenge: Monitoring water clarity is essential for assessing water quality. Achieving consistent positional control for sensors in varying water conditions is challenging.

Solution: RTA’s “MEGA Series” drives, integrated into platforms moving sensors through water, provide a consistent and precise movement pattern. This ensures an accurate assessment of water turbidity, vital for water quality assurance.

Challenge: Ensuring the integrity of vast water distribution pipelines requires consistent inspection. Robots deployed for this task need to navigate complex pipe networks effectively.

Solution: RTA’s “Plus Drive Series” drives can be the heart of these robotic systems. When integrated, these drives power the bots, allowing them to travel seamlessly through pipelines, providing real-time feedback on potential issues. This ensures timely maintenance, minimizing water wastage and ensuring efficient water distribution.

Challenge: Water bodies, especially those used for public consumption, often have varying depths, and achieving consistent precision-based sampling becomes a challenge. Manual sampling may miss crucial data points or be inconsistent.

Solution: Employing RTA’s stepper motors, such as the “NEMA 17” series, which are known for their exceptional positional control and reliability, can be integrated into automated water samplers. This integration ensures that samples are taken from accurate depths, maintaining consistency over time and ensuring that water quality is regularly and effectively monitored.

03. Machine Vision Systems

- Challenge: Water pumps play an indispensable role in transferring water across treatment systems, reservoirs, and distribution networks. These pumps consist of multiple components, such as impellers, seals, shafts, and casings. Any deformation, imperfection, or defect in these components can lead to inefficiencies in water transfer, increased energy consumption, or even system breakdowns, leading to significant operational downtime.

- Solution with Inspekto S70: Incorporating the Inspekto S70 system at the pump component manufacturing stage ensures rigorous scrutiny. The system can be programmed to inspect individual components, such as verifying impeller blade angles, checking seal integrity, or examining shaft straightness. Moreover, the system can be set up to detect surface defects like cracks, rust, or foreign particles that can impede the pump’s performance. By leveraging S70’s high-resolution imaging and advanced analysis, manufacturers can drastically reduce defect rates, ensure long pump life, and offer better warranties.

- Challenge: Water treatment systems rely on a maze of pipes, each interconnected using various fittings like elbows, flanges, and connectors. Any discrepancy in these fittings can lead to leakage, resulting in water wastage and even potential system contamination. The fittings must maintain strict dimensional conformity, especially when dealing with high-pressure systems.

- Solution with Inspekto S70: The S70 system can be calibrated to perform detailed inspections of each type of fitting. It can verify precise dimensions, ensuring, for instance, that the inner diameter of a flange matches its specifications. Thread integrity of connectors, which is vital for preventing leaks, can be checked for any cross-threading or deformities. The system’s rapid imaging combined with its intelligent software ensures that even minute discrepancies are flagged, thus guaranteeing a secure, leak-free connection in real-world applications.

- Challenge: Water filters are paramount in ensuring safe drinking water. The cartridges, often consisting of complex layers of filtering materials, must be manufactured with utmost precision. Uneven distribution of materials, casing breaches, or misalignment can compromise filtration quality.

- Solution with Inspekto S70: Deploying the S70 system at the cartridge assembly stage offers a multi-faceted inspection strategy. Using its advanced optics, the system can visualize the distribution of filtering materials, ensuring uniformity. The exterior of the cartridge, which often houses critical sealing elements, can be scanned for deformities or potential weak points. Real-time feedback from the S70 system enables immediate corrective actions, maintaining a consistent production quality.

- Challenge: Valves regulate water flow within treatment plants, distribution networks, and end-user premises. Given the variety of water sources and treated water’s critical importance, these valves, along with their actuators, must perform flawlessly under varying conditions.

- Solution with Inspekto S70: Integrating the S70 system into the valve manufacturing line ensures a dual-level inspection process. On one hand, the system checks the physical attributes of the valve, like its seating, flange alignment, and internal pathways, ensuring smooth operation. On the other, it evaluates actuators, confirming their fitting and movement range. By conducting these thorough inspections, the S70 system guarantees the production of high-quality, reliable valves.

Want to know more about our custom solutions process?

Discover the automation that fits you best